Even the most skilled manufacturers and most advanced machines can’t prevent a few faulty products from leaving the production line. The raw materials were lower than usual quality, there was an unexpected machine issue, or your workers got distracted – such things happen.

What’s important is making sure that those defective products won’t get delivered to your customers – especially if you are selling food and drinks, medical products, or electronic devices. Otherwise, you might have to deal with a costly and frustrating product recall.

Here’s where lot numbers come in, helping you track products through the entire production process and quickly spot the faulty ones. And in case you do need to handle the recalls, batch numbers make the process much smoother by letting you pinpoint which batch exactly needs to be replaced.

What exactly are lot numbers, and how can they help you enhance your product tracking and recall management? We’ll tell you everything you need to know in this article.

What are lot numbers?

A lot number is a unique identification number assigned to the same batch of items produced. You might also have heard of those being called batch numbers, code numbers, or lot codes. In Prodio, we use Prodio ID codes assigned automatically to each task or item in the system for this.

Those lengthy codes might seem like a random combination of letters and numbers, but they actually hold plenty of essential information.

With simple LOT numbers you can learn about:

- Production date: The date when the product was produced.

- Production history

- Identification number of the technology used or product order

The extended lot numbers meanwhile also include:

- Location: Specific manufacturing facility or location where the product was made.

- Batch or lot code: Each number has a unique identifier through which manufacturers can distinguish one batch of products from another

- Expiration date: In some industries (like pharmaceuticals, food, and beverages, or chemicals), the lot number also might include an expiration date after which the products shouldn’t be used.

- Ingredients list: By analyzing the lot number, manufacturers can also learn what materials or ingredients were used to manufacture a given product – for example, to track a specific face cream ingredient that turned out to cause allergic reactions.

These elements together create a lot number that acts as a “fingerprint” for each batch of products.

Lot numbers are especially useful for manufacturing businesses in industries where tracking the state and safety of their products is essential, such as:

- Pharmaceuticals

- Food and Beverage

- Cosmetics

- Automotive assembly

- Products for children

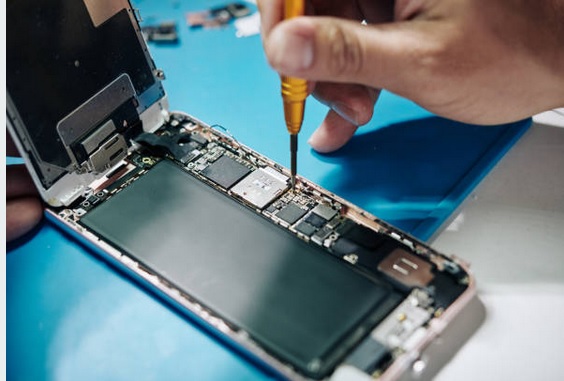

- Electronics

- Chemicals, etc.

What is lot tracking?

Lot tracking allows manufacturers to monitor their products during the entire supply chain and trace them back to specific batches or lots. It’s like giving each batch its own unique ID card so you can easily identify it later on. For lot tracking, manufacturers typically have a dedicated system that stores the data about each product or task and then allows them to quickly check the product details, for example when they get a complaint.

That way, they can quickly find a specific order and then check the product parameters, production history, and consumption of raw materials just by looking up the number, for example, 304/2023.

This is super useful for manufacturers because it helps them track things like when and where a batch was made, what ingredients were used, and to where each product was shipped to. So, if something goes wrong or they need to recall a product, they can quickly pinpoint which batch is affected and take appropriate action.

Why are lot numbers important?

To show why exactly you should use lot numbers and what the difference is between simple and complex Lot numbers, let’s look at those two examples.

Example 1

You are manufacturing simple plastic items, such as gaskets.

One customer called you with a complaint that out of 1,000 gaskets they bought, 400 are damaged and gave you the ID number of the order. After checking the code in the system, you learn that for the entire production batch, two machines were used and three operators were in charge of the order. However, you also learn that elements belonging to the faulty batch were only produced on machine no.2. After you check the machine, it turns out that the clamp is broken.

You can then alert your workers that the given machine is “out of order” to prevent them from using it until the clamp is fixed – eliminating the root cause of the issue with gaskets.

Example 2

Let’s say that your business creates and sells toys for children.

Sometime after sending the newest batches to toy stores and supermarkets, you learn that some children developed an allergic reaction after playing with the latest plush toy from your company. Seeing as the complaints seem to be related only to the newest toy and most of the kids got ill at the same time, it’s clear that the issue must lie in the recent batches.

Still, how can you determine which plushies are causing the allergy reaction and which are perfectly safe? How do you know where the defective products are sold? And how can you inform the families with defective toys at home that they have to send them to you for replacement?

Lot numbers hold the answer to all those questions.

By checking the identifiers of the defective plushies, you can learn:

- From what batch they came

- When and where exactly were they produced

- What materials were used for the production

- And to where the specific batch was shipped to.

Based on the information, you can then investigate what exactly went wrong during the production of that particular batch. Plus, since you know which stores still have the toys from the faulty batch, you can call them directly to ask them to remove those toys from their stores.

What are the main benefits of using Lot numbers?

From the example, you can see the first major advantage of using lot numbers – they make finding faulty products and recalling them much faster.

If you don’t use lot numbers in your facility, then to pinpoint the reason why some of the products are defective and isolate the damaged products from the rest you would need to:

- Remove the entire product series from all stores

- Examine them to see which products are safe and which are faulty

- Talk with the supplies and workers to see whether they have noticed any issues

That would take plenty of time – and in some cases, would be even impossible to do. By using lot numbers though, you have all the information you might need for quick action right in the system – from which exactly batch must be recalled to which stores have the items from the set.

But there are a few more ways in which lot numbers can make managing your manufacturing goods easier.

Improved quality assurance process

As skilled as they might be, your workers are still human. So it might happen that they will overlook a product defect during quality control or forget to remove the expired products from the inventory. Still, shipping off discolored t-shirts or, worse, yogurts with 3 days left until they no longer should be eaten can have disastrous consequences for your brand.

Lot numbers can give your workers a hand here. Once the quality control team finds a defective product, they can inspect the product code to see from what batch the product came and then look through the entire batch to check if there are more faulty items. That way, the damaged items can be removed from the set before they are shipped – saving the company the time and cost they would have to spend on recalling.

More efficient inventory management

Inventory management can also be made easier with lot numbers.

Using those, manufacturing business owners can better track how many ready products they have in stock, down to the amount of each product variation. For example, if you sell one mp3 player type in five different colors, by using lot numbers you can monitor how many devices of each color you have in stock and send the right items to the customers.

For storing products with an expiration date (food products, drinks, medicine, etc.), using lot numbers is especially important. By keeping track of those, you can make sure that items with the shortest date are shipped first and that all expired products are removed from the inventory.

More control over the supply chains

Ever had a situation where one of your products was sent back to you as faulty, but you couldn’t track where exactly the issue started? Lot numbers can be a solution to this problem as well.

By examining the product’s batch number, you can learn where and when the item was produced and what materials were used during the production. This way, you can find out where precisely the issue lies – for example, that most of the returned products used raw materials coming from the same supplier.

Ensuring legal compliance

Many industries, such as pharmaceuticals and food production, have strict regulations regarding product quality and traceability to ensure that the products the companies sell are fully safe for the customers. Here’s where lot numbers can be especially useful, as they can give the companies all the information they might need for tracking and documenting the production process for auditing purposes.

Boosting customer satisfaction and trust

Lot numbers can also increase customers’ trust in a given manufacturing brand. When customers see that a brand uses lot numbers, they know that your company takes safety seriously and that in case of any issues, you will be able to quickly identify the source of a problem.

Moreover, having a lot number can also make it easier for you to ask the customers to either throw away the contaminated products or send them to you for replacement or refund. For example, you can post information about the issue on all of the social media accounts you manage, along with the lot number of the faulty item and details on how customers can return the product.

How can Prodio help you to add lot numbers to your products?

You might think that as valuable as the lot numbers might be, those are something that only large factories can afford to use. Aren’t production management software pretty expensive after all?

We have good news though – with the help of our Prodio, you can start adding lot numbers to your products and tracking them in a matter of moments. Prodio is one of the easiest-to-use MES systems, made for smaller and middle-sized manufacturers, with which you could solve many of the batch tracking issues almost immediately.

From its user-friendly online production scheduling and tracking module you and your employees can:

- See what and in what order they should produce and also have a detailed parameters or requirements list next to the task

- Register their work time and progress on a given machine just by clicking on the “Start” and “Stop” next to a given task (which gives you a detailed work history for each LOT number)

- Register batch numbers of raw materials used for production for full traceability

- Print pallet cards and identification cards that go to production (including barcodes with the LOT number)

- With the inventory module, they can also send to and receive goods from the warehouse or send supply orders

That way, by implementing Prodio, you could both improve work efficiency and streamline the production but also reduce errors and production losses – thanks to real-time production data.

So whether you are looking for a solution to track your products or handle recalls, Prodio can help you with those. Try out the 14-day free trial to see how much time (and nerves) you can save with it on managing your production and your inventory.

Conclusion

Having 0 faulty products during your production runs and entirely avoiding recalls is sadly impossible. With the help of lot numbers though, you can find and remove those items before they leave your manufacturing site – and make your customers doubt your brand.

And in case you need to handle product recalls, lot numbers can highlight which batches you should recall and which are perfectly fine. Add to it that batch numbers can help manage your inventory better, and you should see it clearly now it’s worth it to have them in your facility.

Lot numbers in manufacturing FAQ

What are lot numbers?

Lot numbers are unique identifiers assigned to a specific batch or lot of products during the manufacturing process.

What is the difference between lot numbers and serial numbers?

Lot numbers are assigned to batches or groups of products, while serial numbers are unique identifiers for individual items within a set. Serial numbers are often used for product authentication (for example, for warranty tracking), while lot numbers help manufacturers to monitor product quality and facilitate recalls across the entire batch.

Why do manufacturers use lot numbers?

Lot numbers can provide manufacturers with plenty of important information about the product’s origins. For example, by looking at the batch number, they can find out when and where the product was manufactured, what components were used, or by when the products should be used.

How can lot numbers assist in quality control?

Lot numbers can help manufacturers track and remove defective items by highlighting to which batch a faulty product belongs. What’s more, lot codes can also aid them in managing their inventory and making better use out of inventory management techniques such as First-in-first-out (FIFO).

By keeping track of the expiration dates via the lot codes, manufacturers can ship out first the products with the shortest date and also have the expired products highlighted so they know which products need to be thrown out.

Are lot numbers required for all products?

No, they are not. Lot numbers are only required for companies from specific industries, such as pharmaceuticals, food, automotive parts, or cosmetics, to ensure safety and traceability.

How can consumers benefit from lot numbers?

Lot numbers can reassure customers that the products went through a strict quality control process and are fully safe to use. And if there are any problems with the product, then by using the batch code, manufacturers can faster find affected products, find out the reason for the issue and replace or refund the customers for those items.

Marek Mrowiec

Marek Mrowiec