Supposedly it’s not the first time you searched for production management software. Usually, it turned out that you would lose flexibility because of too many production options in ERP and be forced to hire someone to fill out all required data…

We also know that due to many leasing contracts for CNC machines, usage of tools and last but not least, the costs of remunerations, you are still searching for something, which would help you to increase profitability.

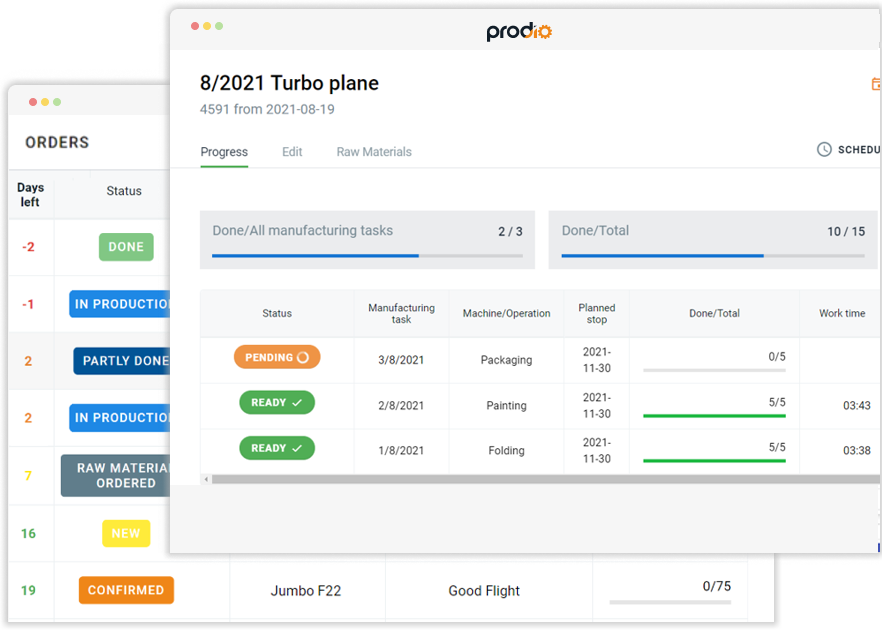

Prodio is an answer to all your problems, as you can find all you need for your employees to know precisely what to do, when and how. In addition, the data is available in real-time, so you can make fast decisions to increase efficiency and simplify work.

In your industry trusted us small companies:

Join hundreds of companies from your industry

Start 14-day free trial Quick wins with Prodio Industry tips&tricks

You will get all the necessary tools to manage your production and metal processing effectively:

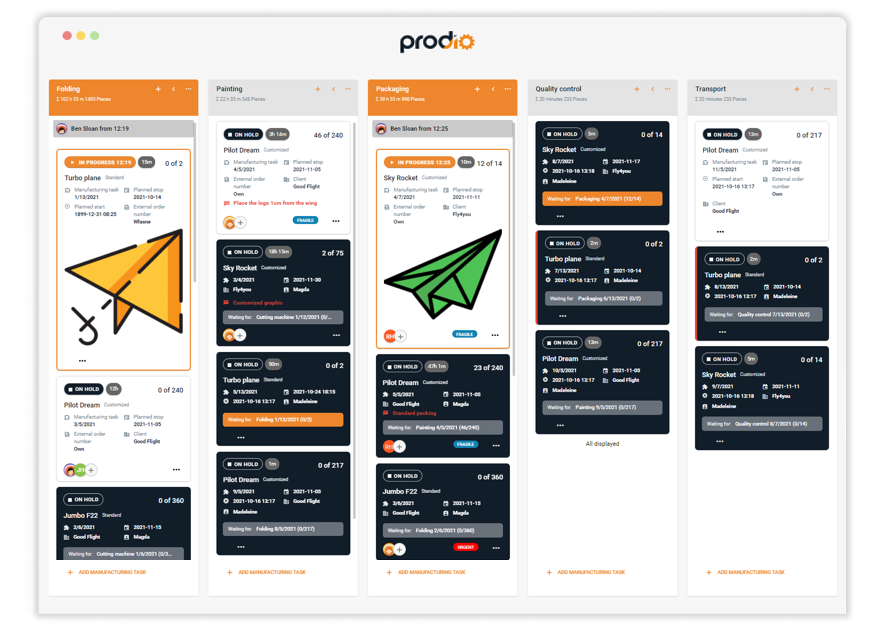

Forget spreadsheets/whiteboards at the production hall; thanks to the kanban style board, you can prepare a faster and more precisely plan of work for machines – especially including estimated machines occupancy in hours/ days /weeks …

Forget spreadsheets/whiteboards at the production hall; thanks to the kanban style board, you can prepare a faster and more precisely plan of work for machines – especially including estimated machines occupancy in hours/ days /weeks …Don’t be fooled by a simple form; thanks to clever modifications in the schedule, you can incorporate:

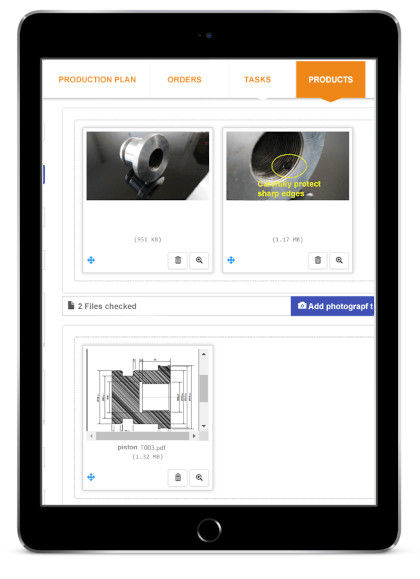

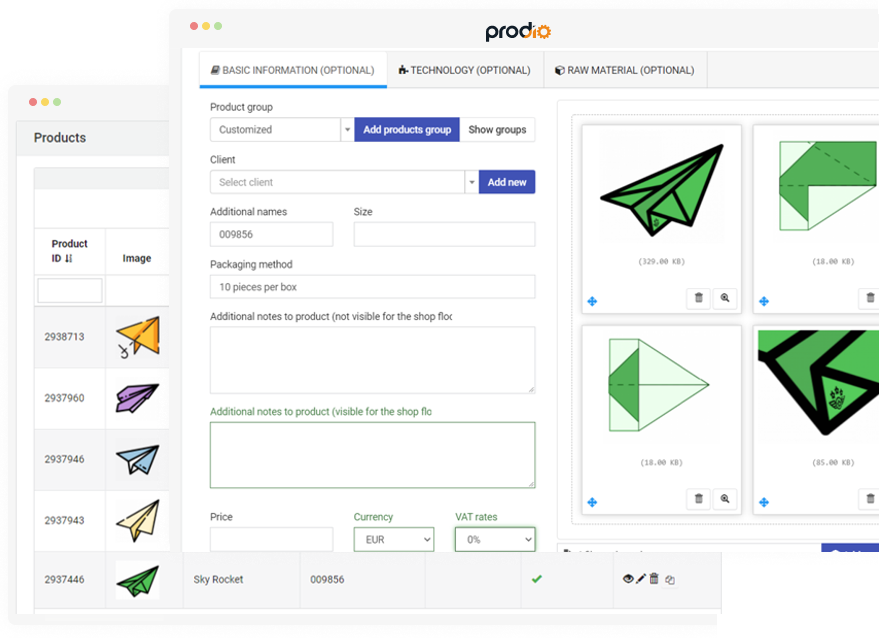

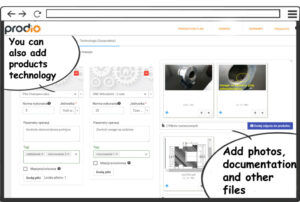

Transparent product technology in Prodio allows you to collect all information on the product-making process and necessary know-how, the sequence of operations, and estimated efficiency in just a few simple steps.

Apart from parameters, you can add product visualizations and photographs, technical drawings, or programs for particular machines. Also, see how to attach large files without uploading them to a website.

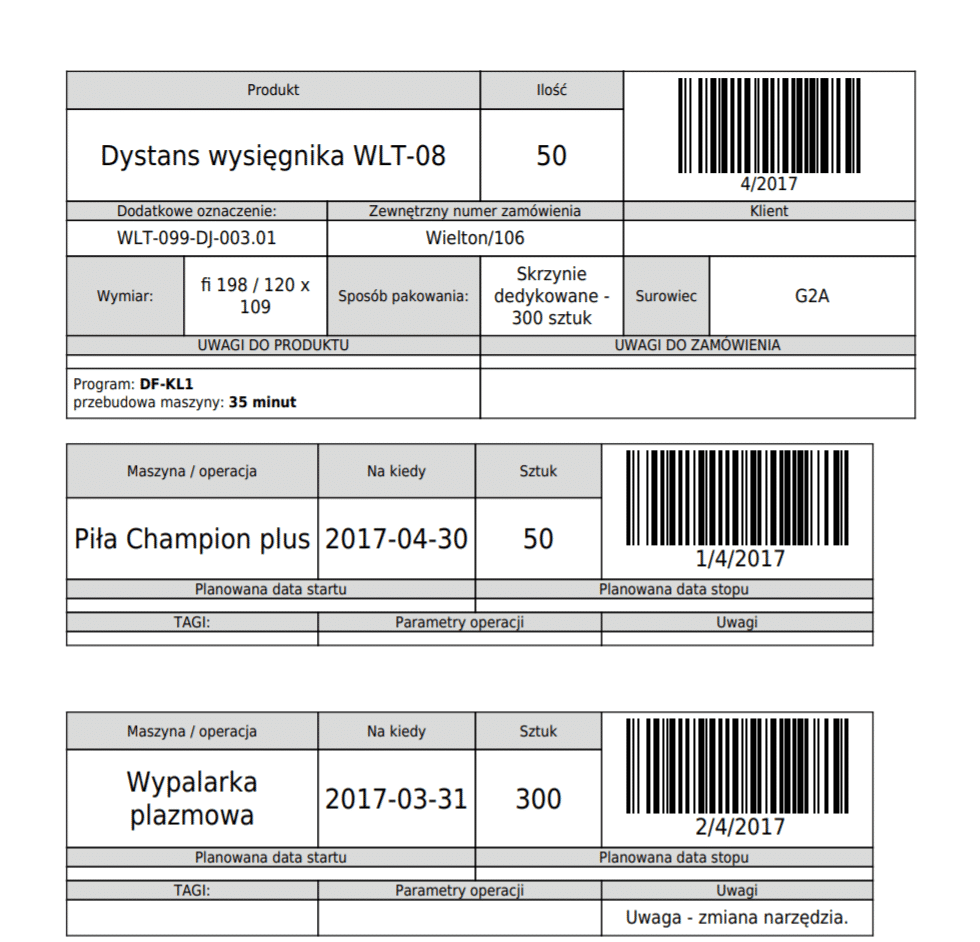

To organize your production hall even better, you can print with one click technological guides containing all information about the product, which can follow the production path making work clear and easy – print a production order (technological guide with production orders and bar codes used to register work).

FIND OUT MORE

Thanks to Prodio, you don’t have to worry about most requirements regarding ISO 9001 / TS 16949 / Factory Production Control. It is possible to throw away many forms, product cards and paper orders – all you need is on your computer.

Because you can also attach PDF manuals and control guidelines, as well as photographs of potential product defects, you can really lower deficiency, and the QUALITY catchphrase becomes a reality. The time spent on training new employees is also shorter.

As a bonus, certifying authorities will be truly impressed and Clients positively surprised during audits, especially when their “SAPs” might be very often 2 steps behind.

Read more on how to (click the link).

FIND OUT MORE

Manufacturing Software Features

Get rid of paper ordersand track your production right now!

No credit card needed - Unlimited free support

To use a production technology module fully, it is recommended to:

Cards with printed technological guidelines (see how to do it) can be useful as ID cards.

How to print it? Click the link.

Thanks to fully mobile access to the software, you can plan work and take photos directly from your smartphone, especially when it’s a small processing order.

What is best to write down and set as “product” in Prodio:

A particular element you produce – ex. distance. When you offer processing services it is good to set up general products such as “final machining”, and add exact parameters in order details. To analyse efficiency and plan work better add in product options a production technology.

Production plan – what can you set as machines/operations?

It is suggested to use machine MIX ex. FANUC 3-axis, and operations such as welding, final processing and quality control. TIP: Constructors/programmers can be set as separate “machines” to enable following their working time. TIP: Main providers in co-operation can also be set as machines, so you can easily trace the products.

Production plan – tips regarding displaying and planning

Set a horizontal view and divide dashboards for a particular production hall.

Additional boxes, worth adding to your branch:

For a product: Number of CNC program Tool used

Additional TAG-s at the production hall and in the product categories

Changes such as types of mounting on machine and types of finishing (preliminary and final). How to set it: CLICK

We do our best to safeguard your secrets – it is clear that the future of our business depends on it.

In 90-95% of cases, data in Prodio is more secure than saved locally:

– connections to web browser are encrypted,

– the server is located in one of the leading and best-secured data centres in Europe,

– in our company, only two people have access to complete data, and they have financial liability,

– together with security experts, we request a paid simulations of hacking and breaking in to assess and update the level of security,

– separate server archives data a few times a day.

We are ready to sign an NDA agreement upon request of our regular Clients.

How-to guides, articles, video tutorials and all resources you need to use Prodio’s software.

Find answers