Your margins are low because of big competition? The cost of remunerations has constantly been growing, and you rely on labor from crucibles to be done by hand gluing?

There is good news – there aren’t that many branches where you can solve production management and labor accounting problems with such ease.

On top of it, if you want to organize cardboard orders better, so employees will not stand by slotters waiting for a delivery, you are more than welcome to read on ????

In your industry trusted us small companies making all types of packaging:

Join hundreds of companies from your industry

Start 14-day free trial Quick wins with Prodio Industry tips&tricks

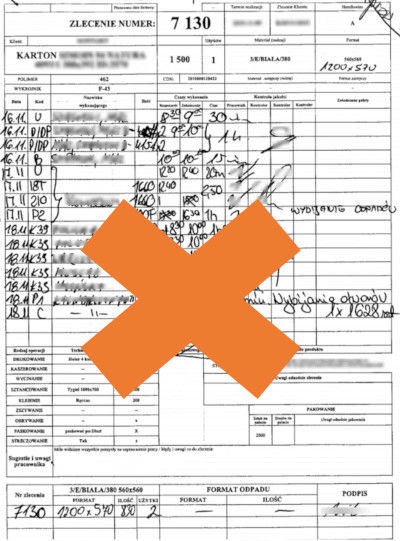

Even though you use a computer, a paper document with parameters and packaging technological description is required in your branch.

Instead of filling out the order form by hand with one click, you can print a clear manufacturing order for a production hall, with all necessary for completion parameters.

As a bonus, you get bar codes on your order form, and thanks to them, work registration is even faster.

FIND OUT MORE

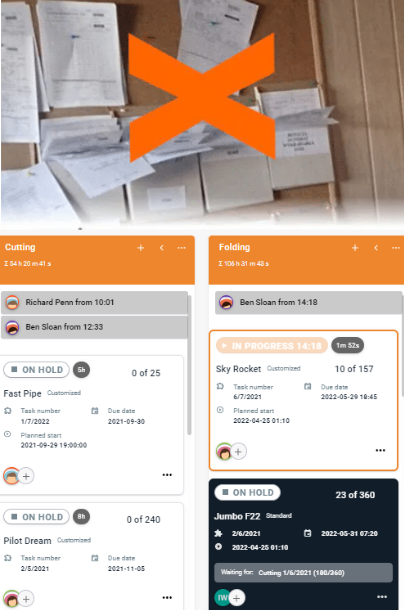

Now your employees will always know what to do. Are you afraid that they might not have sufficient computer skills? Don’t be – we made it as easy as possible and intuitive.

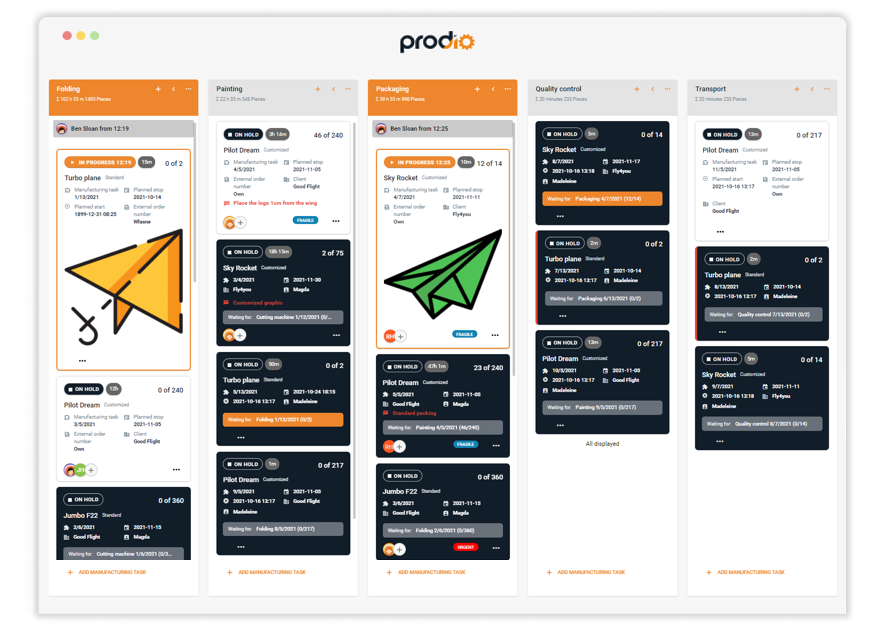

Thanks to production technology, orders automatically are divided into particular slotters, crucibles or glueing – and you save your precious time!

FIND OUT MORE

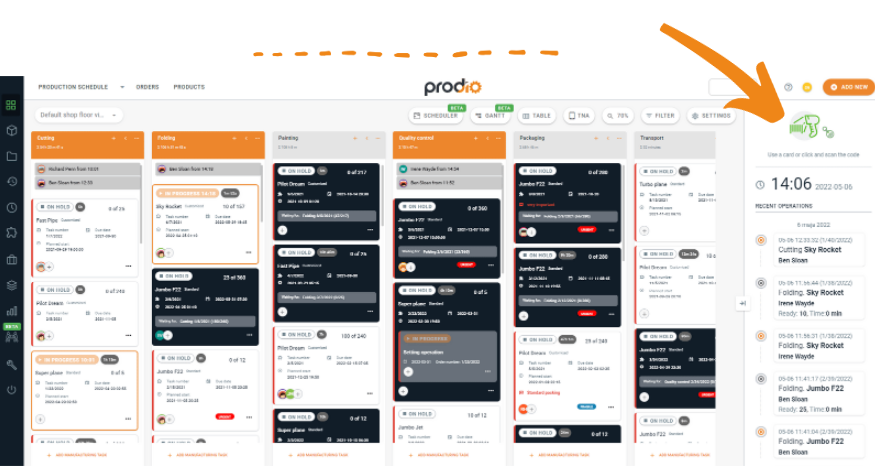

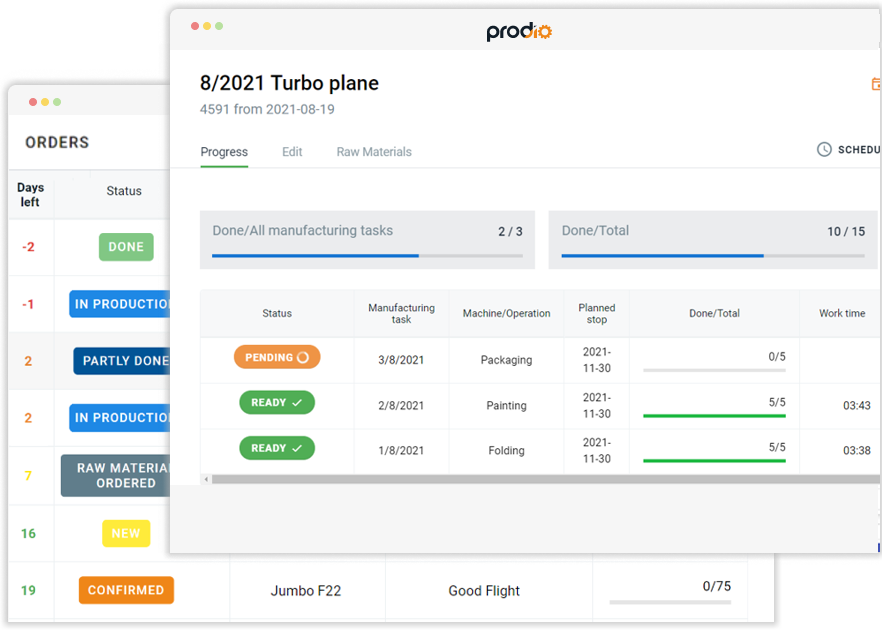

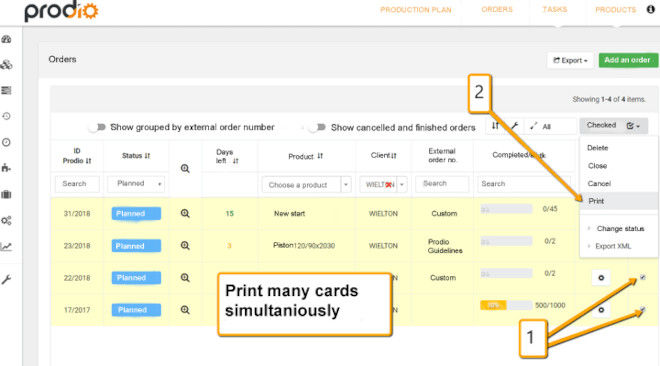

Imagine a clear list with all orders included, with their status shown, updated timing, type of cardboard used, punching die number, graphics and visuals…

…additionally, this list is constantly updating each time an employee enters new data. Sound like finally a dream come true – it’s possible in your branch – see for yourself ????

FIND OUT MORE

Do you have to deal with a high turnover on the production floor? Do you base the pay rates on the number of pieces made?

You may spend long hours on payroll, counting working time and trying to find dangerous and costly anomalies or fix problems with an optimal solution. Prodio gives you instant access to necessary information. With one click, you can export necessary data, i.e. work history, to MS Excel, where remuneration will be easy to calculate.

Would you like to keep track of the consumption of cardboard and avoid material shortages? Now it’s possible:)

Get started todayManufacturing Software Features

Get rid of paper ordersand track your production right now!

No credit card needed - Unlimited free support

When you set Purchaser as the “Machine” in the technological process, he will know to see what kind of cardboard shall be ordered and after he can check the box “ordered” – it will be a clear message for the person working the first machine that everything is ready and the production procedure can be started!

If you want to appear more professional – prepare a separate machine for both a purchaser and stock boy, making checking progress more effortless, and create an individual parameter “Where was the cardboard ordered” for the order itself.

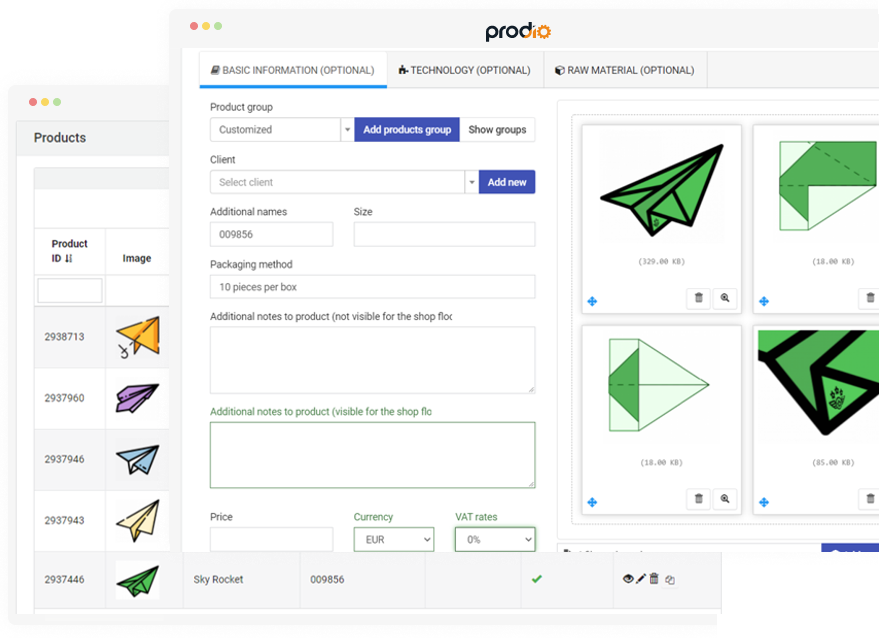

What is best to write down and set as “product” in Prodio:

When you are going to prepare a product for your client more than once, it’s recommended to enter it into your database. Use the technology tab and set machines and their order as a default mode. Remember, you can duplicate products and prepare various types based on one well-prepared template.

Production schedule – what can you set as machines/operations?

All machines (their names) you use in the production process plus manual operations such as glueing, packaging, etc. Add a warehouse boy and the shopper as machines in the process.

Additional boxes worth adding for your branch:

To the product: FEFCO number, the cutter number, polymer number, Type of print: number of colours, pricing (it is possible to hide it in the Settings), delivery method.

You may find interesting:

More than 50 tricks in Prodio to make production management efficient How does Prodio’s production plan work? Efficient production calculation and accounting How to print production orders and register them based on their bar codes.

Yes, it is. Otherwise, it wouldn’t be possible to register production effectively in your branch.

Yes, it is. It is possible to create different technological sequences as the product’s technology part, displayed on the shop floor.

We do our best to safeguard your secrets – it is clear that the future of our business depends on it.

In 90-95% of cases, data in Prodio is more secure than saved locally:

– connections to the web browser are encrypted,

– the server is located in one of the leading and best-secured data centres in Europe,

– in our company, only two people have access to complete data, and they have financial liability,

– together with security experts, we request a paid simulations of hacking and breaking in to assess and update the level of security,

– separate server archives data a few times a day.

We are ready to sign an NDA agreement upon request of our regular Clients.

How-to guides, articles, video tutorials and all resources you need to use Prodio’s software.

Find answers