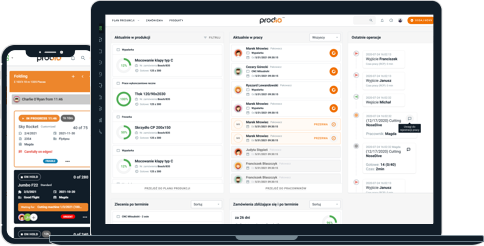

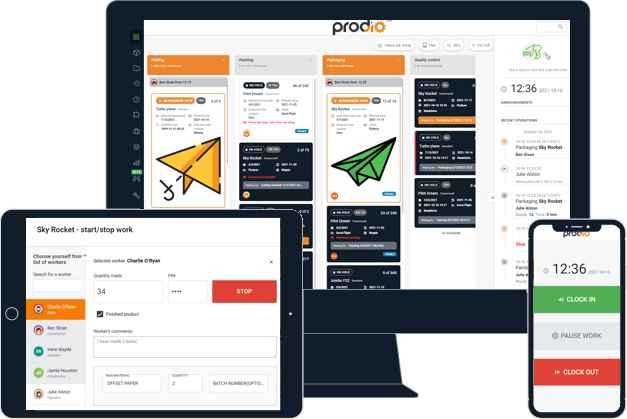

Manufacturing software features

Control stock levels and material flow without hundreds of restrictions as in ERP systems

Since 2016 we have registered millions of manufacturing operations and helped people all over the world.

Join hundreds of companies: START a 14-day trial.

READY TO CONTROL YOUR SHOP FLOOR?

See who’s on shift or running late, who forgot to clock-in/ out, and who’s on break.

It’s very simple

Get set up in under 15 minutes

Start a free trial

Start your 14-day free trial to try Prodio risk-free. Unlimited free support. No credit card needed.

Get setup in minutes

Add some products with their technology to schedule your first manufacturing order. Track time and progress.

Select your plan

We recommend the Optimal plan to have access to all features. No expensive setup fees, costly training or lock-in contracts.

Yes, you can. It’s not a problem – just write to us and the following month we will issue a modified invoice. It works in the same way if the number of employees in your manufacture changes and exceeds the one in your package. We simply make adjustments.

The way we understand it, a manufacturing worker is a person who can register in the system the start / the finish of an operation and respectively clock in / clock out. All staff having only administrative access, but not performing any production are not included in the limit precised in the package description.

For the security reasons and protection of your data, the connection with the server is encrypted SSL 128 bits). Servers are placed in the professional server’s room equipped among others in a backup electricity generator, security cameras monitoring servers room and access control.

After registration you are welcomed by a tutorial, where you are given a short tour explaining basic functions of the system and shown how it works.

An annual subscription (“per YEAR”) means that you pay for one year upfront and receive a discount comparing to monthly payments. This is the most popular choice among Clients as it’s comfortable and cheaper.

No, you don’t. there isn’t a minimum period to commit to a subscription payment. You just buy in advance a month’s subscription and simply use it.

If you don’t pay your subscription fee your account will be automatically suspended without any financial consequences. You simply stop using the product and after a while or at your request the account might be completely deleted.

Basic computer skills are enough to go through configuration, which takes approximately 15 minutes. You answer a series of simple questions to configure Prodio for yourself. If you experience any difficulties you can rely on our technical support to help you.

There aren’t any additional costs. The price listed in a selected subscription package is complete and includes costs of using the software. All updates automatically appear on your account and there isn’t any additional payment for them.

How-to guides, articles, video tutorials and all resources you need to use Prodio’s software.

Find answers