Using MS EXCEL template is a low-cost solution that works for small-scale manufacturing. But as soon as you start scaling production, keeping your manufacturing spreadsheets up to date will cost you more than you think. In manufacturing, an Excel spreadsheet is used to record data, but converting it into something that can be understood is another story. That’s why getting total task-level control of your shop floor and orders can be tricky with templates. Also, although spreadsheets are great for a team of one or two, the more people make edits and updates to your file, the higher the possibility of mistakes occurring — not to mention all the administrative work.

Of course, Ms Excel – is a beast tool for production analyses. Helpful in some regards, but confusing and easy to screw up. It is often prone to human error in the recording process, not available in real time, and requires extensive work and time to create any reporting dashboard.

ARE YOU STILL STUCK IN THE 90s USING EXCEL AND PAPER NOTEBOOKS? IT’S TIME TO MOVE ON.

Which analyses you can find in the MS Excel template?

Take a shortcut and check out which analyses you can perform using the Excel template:

Among advanced production analyses are:

- Work history

- Machine analyses

- Product analyses

- Worker analyses

- Occupancy of machines and operations

- Collective order analyses

Check out this video to see what is inside a free Excel template:

Why do some manufacturers still use a spreadsheet?

Not to sound redundant, but manufacturers keep literally everything in spreadsheets. Those can include data from manufacturing orders, downtime, maintenance schedules, quality data, and time and attendance. You name it, and it’s probably included in a spreadsheet.

It goes without saying that an Excel template is a step forward compared with the traditional method of pen and paper to record data from the shop floor. Sometimes workers write down data on a piece of paper every hour. Maybe at the end of every shift. While later, it is transferred to a whiteboard, day by hour board, or production board. It takes a lot of time and effort to record and calculate the data when those efforts could be better spent on doing something else or growing the business. And most of the time, it happens to be a company owner’s responsibility to go over the papers, find mistakes, or double-check.

Collecting data via pen and paper is not timely because you don’t know what’s happening now. And, it’s not accurate because no matter what, there will be the potential for human error. Manual reporting is also not lean.

For many small companies, getting rid of paper on the shop floor and using Excel templates for production analyses is a first step in changing the data collection process. But, of course, the manual method is riddled with the potential error: someone performs the calculations in Excel and eventually distributes the report to the key people, which is problematic because the data collected is not timely and not accurate.

MS Excel spreadsheets were created to analyze data, giving great possibilities to visual tracking. Contrary to registration and managing the production process, spreadsheets for calculating make more sense.

Each of the tens of companies that use Prodio uniquely analyzes data — that’s why while creating Prodio manufacturing software, we wanted to allow exporting information to Excel in an easy way.

Prodio allows you to check the actual cost of labour of each detail (resulting from the cost of man-hours), compare planned time with lead time, sum things up using various filters, and compare any given data in hundreds of ways.

You don’t have to be an “Excel mastermind” because we prepared some ready-to-use files to make the whole process a lot easier. However, even when you are familiar with only essential Excel functions, you will handle quite sophisticated calculations.

Ready to Streamline Your Shop Floor?

Online manufacturing software that puts you in control.

Get started today14-day free trial - No credit card needed - Unlimited free support

IMPORTANT ANNOUNCEMENTS REGARDING PRODUCTION ANALYSIS IN MS EXCEL

- OUR TARGET IS TO MOVE THE MAJORITY OF ANALYSES TO PRODIO, SO LET US KNOW WHICH ANALYSES SHOULD BE DIRECTLY IN THE SYSTEM.

Apart from helping you, we would like to use the present spreadsheet form to collect opinions and ideas, which reports should go to Prodio itself.

This is very important for us to have your insight on how it should look. If any comments repeat, we will try to implement them. So far, we have considered adding many new parameters (including OEE, shifts division or machines occupancy forecast).

2. THE SPREADSHEET IS UPDATED CONSTANTLY

The current spreadsheet is a constantly developed version, so it can contain some mistakes / or some elements that might be missing. We will make it better and work on real-time updates after receiving your comments – the newest version can be found when you click the download button.

3. EQUIPMENT REQUIREMENTS

We intentionally used MS Office 2007 to create a spreadsheet (the oldest version possible to use) and ensure compatibility with older versions of spreadsheets. To make analyses, an older computer model is also sufficient.

Analyse and production calculation in MS Excel

Available analyses:

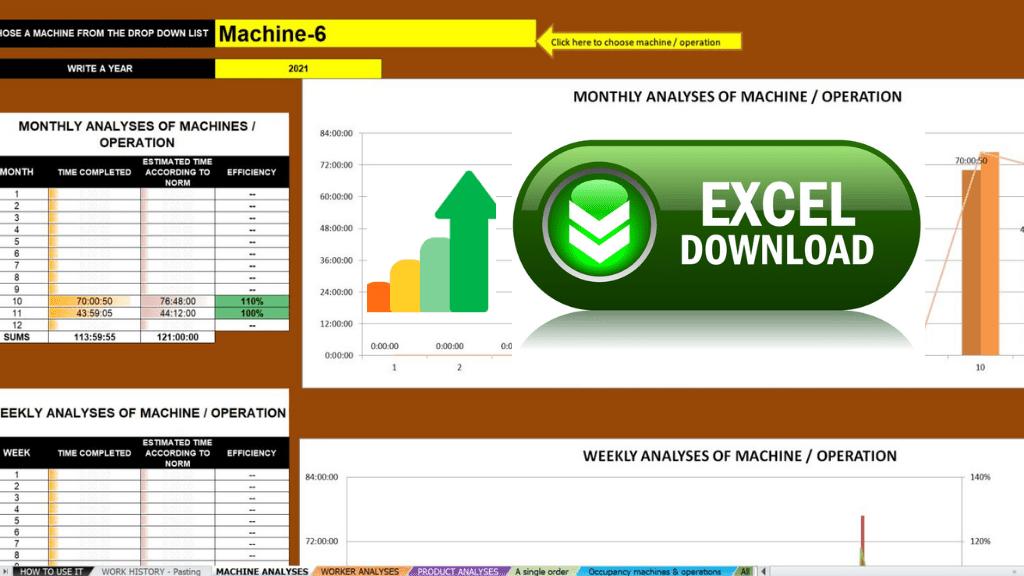

1. Machine and operation – graph

A single machine/operation occupation history (with efficiency and graphs).

In this bookmark, you can learn:

- how much worked a SINGLE machine/operation weekly/monthly (ex. to check occupancy and see if all working stations are used well)

- how long would it take if the machine/operation was doing the same job, but accordingly to norms set in products technology (to see which machines/operations are the weakest or underestimated in your technological processes)

- calculate percentages and compare planned times with lead times from the point of the improvement process.

2. Machines and operations occupancy

The total summary of all machines/operations occupancy.

In this bookmark, you can learn how to:

- easily sum and compare how much worked machines /operations in a particular month (ex. to check occupancy and see if all working stations are used well);

- easily sum and compare how much worked machines /operations in a particular week (ex. to check occupancy and see if all working stations are used well);

- this summary is used mainly to see whether there are any discrepancies in particular processes

3. Employee’s efficiency:

Work occupational history for the particular employee (with efficiency and graphs).

In this bookmark, you can learn:

- how much an employee worked monthly / weekly

- how long would it take if an employee was doing the same job, but accordingly to norms set in products technology (to see which employees are the weakest);

- compare in percentages planned times with lead times from the point of the improvement process.

4. EXTERNAL CALCULATIONS, ORDERS:

Comprehensive production analyses in Excel of multi-position orders (by external order number) are instrumental when you need to quickly summarize — 20 position order without dividing it into single items.

In this bookmark, you can learn:

- how long it took, in total, to complete the whole (multi-position) order

- what was the total time conditioned by the production technology and norms

- compare planned timed with lead times

- see which machines/operations had the biggest discrepancies

- see which employees contributed the most to appearing of those discrepancies while completing the order

- how many pieces were completed and how many shortages were in the process

5. PRODUCT ANALYSES:

A comprehensive production analyses in Excel for a given assortment regarding the whole product making – the best knowledge compendium on your products.

In this bookmark, you can learn:

- how long on average it takes to make a product by particular machines/operations;

- which operations are underestimated, and which can cut from the calculations;

- compare planned times and lead times for each product;

- which processes generate the most shortages

- which employees are the best at completing a given product (in total);

- how efficiently particular employees work on given product/operation;

- how many pieces were made and when (in which months) the production was the biggest;

How to use it – spreadsheet preparation:

- Fill out an above form to get a free Excel template.

- Download it and open.

- Go to a bookmark Working history in Prodio, then click „Export the history of operations”.

- Open the downloaded file with a working history, mark columns A to T and press “Copy”.

- In the analyses file go to bookmark “Pasting”, position mouse in A1 cell and then click “Paste”. The software will ask if you want to change content, to which we mark “YES”, as an answer.

- It’s ready 🙂

Ready to Streamline Your Shop Floor?

Online manufacturing software that puts you in control.

Get started today14-day free trial - No credit card needed - Unlimited free support

Replace Excel templates with a real-time manufacturing planning

It is possible to build a manufacturing dashboard in Excel, but it is incredibly complicated. Production analyses in Excel can become outdated quickly, and it is difficult to share them with multiple people in a company. On top of that, if your company has several locations, maybe each site has its own tab. Someone must summarize all of the inputted information together and then somehow format that data into a dashboard. There is a question: “How can you guarantee that data is 100% accurate?” And, if that data is correct, it still raises the issue that hard-working employees are wasting time by hand-inputting data when it could be summarized for them instantly. The more efficient and more accessible option is to use a software tool to make the data collected user-friendly such as Prodio.

- Ms Excel is a lot to manage for a manufacturer, requiring constant work and updates. The more orders you get, the more important for you is a live update on work-in-progress. Corrupted data is no use for your calculations.

- Transforming data to a manufacturing dashboard in Excel is very difficult. At some stage, a spreadsheet will take more time to update than the time it was intended to save you and your team.

- Wouldn’t it be easier for data to automatically be gathered and summarized? Production analyses in Excel doesn’t guarantee that.

Ready to Streamline Your Shop Floor?

Online manufacturing software that puts you in control.

Get started today14-day free trial - No credit card needed - Unlimited free support