A production schedule process is something indispensable for a manufacturing company. How else would you know how the production is progressing, and are you meeting the deadlines? That said though, writing an efficient production schedule for their current production processes is something manufacturing managers regularly struggle with.

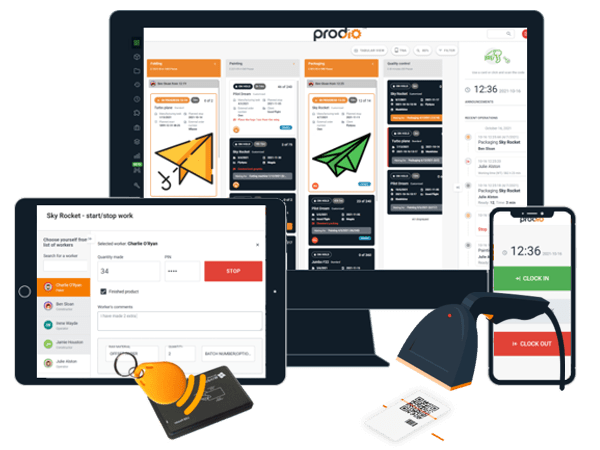

So in this guide, we’ll share some practical tips on organizing a production schedule and production planning: from how you should organize the schedule to how to divide the production process into stages. We’ll also show you how a manufacturing execution system (such as our Prodio) can make building efficient and clear for everyone production schedules a breeze.

Why do production managers have so many difficulties with production scheduling?

Whenever it’s time to write a new production schedule (especially for a complex process), factory managers typically have dozens of questions that need to be answered.

- According to which elements it is best to organize it: machines, business operations, procedures, stages, employees, delivery dates or maybe something else?

- How to create a production schedule that includes and reflects ideas you have in mind and simplify the whole production planning process?

- What is the best way to divide the production process into different stages?

The production schedule organized by machines, operations, procedures, or maybe the stages of work? This matter seems trivial, mainly if we talk about your company, which you know inside out, so creating a continuous production schedule might seem like a piece of cake. However, the practice shows an urgent need to address this issue; we have received a significant number of questions via the customer support chat box and created numerous attractive solutions together with our Clients. ????

The way you organize your production schedule will often determine the implementation process’s success, production capacity, speed, and course.

Many wrong production scheduling and planning (ideas of having a complicated work schedule or artificial correctness in adjusting to some form) result from complex production systems ERP implementations. Some things are done to serve their purpose. Consequently, you end up with a useless and expensive tool and do most of the planning manually, using the old methods.

So it’s not the advanced or sophisticated functions that should matter during the scheduling. Rather, you need to look at your orders and SEE and FEEL your production processes. If this one is met, then you might find out that you love this new software for production planning that is made to make your life easier. Otherwise, you might just get back to your old ways and plan production in your head, ignoring advice from the production planning software.

5 tips how to organize an efficient production scheduling

#1. Ditch the theory – organize a production schedule according to what you have in mind

Ensure that you can see the shop floor in your manufacturing facility just in the way you think of it whenever you look at the production schedule. Remember that if you or your workers look at the production schedule and can’t “feel” it, it’s not a promising sign.

Answering the question which appears at the beginning of this article, we can say that practically speaking in 90% of manufacturing companies, a transparent, clear, and simple production schedule is a mixture of:

- machines

- technological operations

- and stages and procedures.

…that’s right. Therefore, only complex and not flexible ERP systems can dictate your production schedule elements, contrary to Prodio, where you can do things as you wish and adjust them to your own needs.

Having hundreds of successful implementation cases below the belt, where company owners use and love the Prodio production schedule, we think there is one best answer to the question “According to which elements organize production schedule?”.

And this is “Organize it according to how you think about your production”. Most likely, it will be a mixture of machines, processes, suppliers and stages as well.

Case study

A company produces a wide range of bespoke furniture, and the business is growing. Although there are more and more new machines in different departments, it is still the most important for the company owner, who plans things in his head, that people know how and what to do, so he can calculate total production time.

Each machine is occupied is not the key because there are thousands of elements in each project, and workers can change the order of things to suit the progress.

Imagine that instead of operation “Boards preparation” consisting of a queue of different tasks, he would have to split them into CNC cutting machines dedicated to wooden boards, plotters, saws, band saws, etc. The owner would probably give up before delegating tasks to the production hall.

Even if the order gets there, the workers could confuse things between the machines. They wouldn’t check things every few minutes with the computer, relying on their professional knowledge and expertise.

#2 Make sure the plan is clear and simple…but not too simple

The more you divide your production into tiny elements, detailed workstations, tens of-minute operations, even when you have good intentions to tackle all the problems with your production scheduling software, there is some risk that you and your employees might feel overwhelmed by data provided, stuck in numerous columns, hundreds of orders.

As a result, things that seemed easy previously now might appear to be complicated or chaotic.

Ready to Streamline Your Shop Floor?

Online manufacturing software that puts you in control.

Get started today14-day free trial - No credit card needed - Unlimited free support

Case study

The company, which prepares microbuses based on the conversion of delivery trucks changing from paper orders to the Prodio system, divided all operations during each stage into detailed elements. For example, the works on the new wiring loom had several operations. Installation of the fridge, LED panels left and right, neon sign installation, tv-sat cables, etc.

What’s important is that two people were in charge of all electrical works for the particular project and did everything in two stages separated by installing new elements. From the project’s perspective, it wasn’t necessary to check in every 5 minutes with each detail or operation. The boss needed a precise calculation of the total working time and hours spent on each car conversion to know if it is ready for the following production stage.

On the other hand, a simplified production schedule might seem more transparent at first sight, but it DOESN’T GIVE you any added value. Because the production schedule is too general, you or your workers must physically go to the production hall to check what’s happening there.

Here’s another example.

If you operate in a paint shop, where each element has to be first prepared for painting, then painted for the first time, sanded, painted for the second time, and finally is ready for annealing, if you have only one operation named “Paint shop” it won’t do the trick. Tens of orders in different stages of the painting process will mix.

When you intend to see when, for example, the rim order will be ready, all you will see in the system is that the order is in progress at the “Paint shop.” It won’t tell you how advanced the work is or whether the order is stuck somewhere between sanding and second painting operations.

#3 Focus on key resources – also those outside the shop floor

If you lack an idea of organizing your production schedule, focus on listing all the places where bottlenecks most frequently appear or name operations that are most likely to be on hold waiting for the previous procedure to be finished.

Production scheduling can have multiple roles, starting with the TIP 1 situation when you feel and see what is happening at your production hall. It’s vital to plan the proper queue during most essential operations, where bottlenecks tend to appear.

For example, does it make sense to divide an operation into three separate machines if, in reality, you still have only one experienced worker who works on one of those machines at a time? In such a situation, the only thing you create is chaos because you will lose clarity.

It would be a much better solution to use the operations, namely in the comments/tags of tasks assigned to the machine operator, to indicate which of the three machines he is supposed to use and when.

Similarly, if a given operation delays work, the following stages have to wait, which creates a bottleneck. Therefore, it is recommended to mark it at the production schedule. This will significantly improve communication. A good example could be adding to a production schedule a quality control procedure that would free the product to go to the next stage or allow technologists to prepare programs for the machines.

Thanks to this solution, the workers at the following production stage know if a given order is ready or still on hold.

#4 Include other operations in the schedule that are not limited strictly to production

It is a great practice to include other operations not strictly associated with production in the whole manufacturing process. This improves the organization of work in manufacturing companies.

For example, some clients set the first operation on the production schedule, “Preparation of technological documentation” in the office. At first glance, it might seem a bit strange, but it is a beneficial and practical solution. On the first machine tool, the worker may have several orders in the queue by his manager/planner.

Still, they can see in real-time which ones are ready to start and which ones are on hold because of incomplete documentation or missing programs for the machine tool. Unfortunately, due to the lack of technologists, this is the place where bottlenecks appear. That’s why the correct queue of orders is so important.

Other examples include:

- mounting the form on the machine

- furniture assembly

- production of headstones at the graveyard (the latter is a true story – what’s more, the customer divides orders into separate assembly teams)

- external operations delegated to subcontractors such as galvanization or quenching.

We could multiply the examples, but they have one common feature: looking at the production schedule, you are sure that the whole production process is covered in 100%.

#5 Divide a production schedule into dashboards to make the view easier for you and the employees

Remember that clarity is what you and your workers need the most, particularly when deciding to mix a different approach to production scheduling and making a production schedule. That’s why it is essential to separate different production views, and dashboards are perfect for that task.

What are production dashboards? It is the easiest to explain when you imagine them as large-sized separate boards with tasks placed on the wall in different departments of your company. However, as we are in the XXI century, it is more likely for the boards to be in the electronic version, and they would instead display machines.

Thanks to dashboards, each department can see only their area of interest without going into others’ responsibilities and having only relevant machines/operations at the production schedule.

Furthermore, automation and online data processing ensure that particular production orders visible on the production schedule contain information about the progress and the stage the given product is at. That way, communication is constantly improving and gets better and better, even though everything is divided into different production schedules.

Practical example – production schedules and dashboards organized by different industries

CNC machining companies

- Dashboard: construction office

- Different technologists preparing documentation and programs

- Dashboard: CNC machines

- machine FAAC 300mm

- machine FAAC 400 mm

- machine Fanuc 5 axis

- Dashboard: finishing works

- Polishing

- Quality control

Company producing cosmetics

- Dashboard: formulation

- Different reactors / stirrers

- Dashboard: packaging

- Bottling line 1

- Bottling line 2

- Labelel

- Packaging

Carpentry shop

- Dashboard: cutting

- Saws

- CNC machines

- Dashboard: assembly

- Manual assembly operation

- Gluing

- Varnishing

- Dashboard: assembly at the customer’s place

- Different assembly teams and their tablets

How can Prodio platform help you build an efficient production schedule?

Far too manufacturers still rely on spreadsheets or paper notes to design the production schedules. This method might seem like the fastest and easiest to use but what if you want to quickly share the document between multiple workers? Or add last-minute changes to the schedule? Or even simply find out how is the manufacturing process going along?

Then paper notebooks or Excel spreadsheets are no longer cutting it.

With Prodio at your service though, you could say goodbye to paper schedules, several Excel spreadsheets, or multiple calls to your workers to ask about the progress.

Inside the online production planning module, you can build detailed production schedules with ease. Deadlines, priorities, workers assigned, any special requirements or changes – everything will be visible at a glance for anyone involved.

And in case you have to add changes to the schedule? One click to add the changes and second to alert all workers there’s an update – and that’s it!

Or maybe you want to create customized dashboards to divide your schedule into production floors, workstations or assembly teams? No problem – you can create as many as you want.

Do you want to find out can Prodio really make designing new production schedules more enjoyable? Then, how about scheduling a demo presentation or giving our free 14-day trial a test drive? We can bet you won’t ever want to return to manually creating the schedules ever again!

Conclusion

Just thinking about having to draw up another production schedule gives you anxiety? We know this feeling far too well. With our simple scheduling tips, we hope it will be easier for you to write the schedule the way that fits you and your manufacturers the most.

Our Prodio is also ready to help you with the heavy lifting you until now had to handle yourself during detailed planning. Just schedule the tasks inside the app and Prodio will take care of making sure that your entire company know what to do. And if you ever wished that you could be in six places at once just to monitor the entire manufacturing process, Prodio can fulfill that wish for you as well.

Who knows, maybe with our help you actually start looking forward to designing new production schedules?

Production schedule in manufacturing FAQ

What is production scheduling process?

The production scheduling process involves creating a plan to determine what, how much, and when to produce finished products based on customer demand and available resources. The plan also includes all needed production activities, resources that will be used, main production goals and delivery dates.

It aims to ensure that production targets are met within a set time frame and with optimal production efficiency.

What are the benefits of effective production scheduling?

Effective production scheduling allows businesses to ensure on-time delivery of products, minimize inventory costs, optimize capacity utilization, reduce production delays and potential bottlenecks, and improve overall operational efficiency. It also helps in demand forecasting, inventory management, and supply chain management.

How can effective production planning and scheduling improve the manufacturing process?

In several ways. First, a clear manufacturing schedule makes it easier for all workers to understand what tasks they have do and in what order they should be done. When everyone is on the same page, there’s also less room for misunderstandings or mistakes so the entire manufacturing process goes much smoother. And as the manufacturers work with maximum efficiency, the products are ready faster but also there’s less raw material wasted so the production cost is lower.

What are some of the challenges involved in creating an effective production schedule?

Manufacturers often struggle with designing schedules because they can be organized in a number of ways and it might be difficult for them to find the right method. Adding changes to the already running production processes and informing all workers about it is also quite tricky, especially if the production facility owners mostly rely on paper plans or spreadsheets.

What are the key components of a production scheduling process?

The key components of a production scheduling process include demand planning, master production schedule, material requirements planning, production routing, production control, and inventory control. These components help in managing the entire production chain and ensuring the timely delivery of products to customers.

How can production scheduling software help with optimizing manufacturing process flows?

With those tools, manufacturers can create production schedules quickly just by adding tasks to the system and assigning workers to those. What’s more, tools such as Prodio come with a real-time progress tracking system, with which business owners can keep an eye on their production progress 24/7. Thanks to this, they don’t need to call multiple workers to ask about progress and the employees also know at what stage the production currently is.

What is the role of production planning tools in the production scheduling process?

Those tools can manage all manufacturing process steps, create adaptable production plans, keep an eye on operational costs and also monitor key performance indicators for a business. That way, they can help to improve product quality, ensure on-time delivery of products or alert to any issues that might cause a delay (such as lack of supplies).