Growing companies eventually get to a point where spreadsheets no longer cut it. To optimize their procedures and facilitate growth, they conclude that they need an automated system for their production. Most business professionals have heard the term “ERP,” but when it comes to knowing what it is and how it works, there’s still plenty of confusion. Even more when they are trying to decide whether they should go with a full-blown ERP or maybe they should go for something smaller and simpler.

Our guide should answer all your questions and doubts – from what ERP is, how it works, and what features you can find inside it to when exactly you should go with a ERP (and when it’s better to look for something smaller).

ERP definition

You are spoilt for choice when you type the phrase “manufacturing software” in the Google search engine. Thousands of companies have a wide range of products and services, and after spending hours researching, you are none of the wiser. However, some basic definitions should clarify, considering that top Google positions occupy large companies investing in white label SEO and selling sophisticated resource planning systems, which might not necessarily be synonymous with what you are looking for.

ERP is an acronym that stands for enterprise resource planning (ERP). It’s a business process management software that standardizes, streamlines, and integrates business processes across finance, human resources, procurement, distribution, and other departments. Typically, ERP systems use an integrated software platform operating on a single database, which collects and organizes key business information that helps organizations run lean and efficient operations as they expand.

How does ERP function?

Once information is compiled in that central database, leaders gain cross-departmental visibility that empowers them to analyze various scenarios, discover process improvements, and generate major efficiency gains. That translates to cost savings and better productivity as people spend less time digging for needed data.

ERP has evolved from a human resource management application to a tool that spans IT management. For many users, an ERP is a “do it all” system that performs everything from the entry of sales orders to customer service. In addition, it attempts to integrate the suppliers and customers within the organization.

Ready to Streamline Your Shop Floor?

Online manufacturing software that puts you in control.

Get started today14-day free trial - No credit card needed - Unlimited free support

ERP modules

ERP belongs to a category of business software, but its systems comprise various modules, each addressing a specific business requirement. The names and numbers of modules in an ERP system provided by various software vendors may differ.

The most popular modules of ERP target:

- engineering data control (bill of materials, process plan, and work center data); sales, purchase and inventory (sales and distribution, inventory and purchase);

- material requirement planning (MRP);

- resource flow management (production scheduling, finance, and human resources management);

- works documentation (work order, shop order release, material issue release, and route cards for parts and assemblies);

- shop floor control and management, and others like costing, maintenance, logistics, and MIS.

Also, the modules of ERP include areas such as:

- Finance (financial accounting, treasury management, enterprise control, and asset management). This lays at the basics of the ERP concept.

- Logistics (production planning, materials management, plant maintenance, quality management, project systems, sales, and distribution),

- Human resources (personnel management, training, and development, and skills inventory),

- Workflow (integration of the entire enterprise, with flexible assignment of tasks and responsibilities to locations, positions, jobs, groups or individuals).

ERP in practice

How does it look in practice? For instance, the customer relationship management (like Capsule CRM) module tracks all communications with clients, assists with lead management, enhances customer service, and boosts sales. Professional services automation plan and track projects, including the time and resources spent on them. It can simplify client billing and encourage collaboration among staff members working on a project. The Working Time Management (WTM) module keeps track of attendance and hours spent at work and, in some systems, can also manage payroll. It can record absenteeism and productivity by department, team, and individual employees. The list can go on forever.

Each module pulls information from and pushes information into the central database, a key component of an ERP system. This common data repository provides visibility into all departments. It thus allows leaders to evaluate and compare the performance of different business areas and understand the full impact of decisions.

A brief history of ERP

The ERP system traces its roots from standard inventory control packages to material requirements planning (MRP) in the 1960s. Manufacturers used MRP software to plan production schedules, ensure they had all the necessary supplies for production runs, and track finished inventory. It was one of the early business applications that did not belong to finance and accounting. MRP, at its core, is a time-phased order release system that schedules and releases orders so that sub-assemblies and components arrive at the assembly station just as required. Some of the benefits of MRP are a reduction of inventories, improved customer service, and enhanced efficiency and effectiveness.

MRP evolved and expanded to include more business functions such as product costing and marketing. In the early 1980s, MRP expanded from a material planning and control system to a company-wide system capable of planning virtually all the firm’s resources. This expanded approach was MRPII. A major purpose of MRP II is to integrate primary functions (i.e., production, marketing, and finance) and other functions such as personnel, engineering and purchasing into the planning process to improve the efficiency of the enterprise.

ERP – the term is born

The Gartner Group of Stamford, the USA, coined the term ERP in the early 1970s to describe the business software system that is the latest enhancement of an MRP II system (encompasses all MRP II modules).

A key difference between MRP II and ERP is that while MRP II has traditionally focused on the planning and scheduling of internal resources, ERP strives to plan and schedule supplier resources based on dynamic customer demands and schedules.

Who uses ERP?

ERPs were originally designed for manufacturing companies but have since expanded to service industries, higher education, hospitality, health care, financial services, and government. Each industry has its own ERP peculiarities. For example, government ERP uses contract lifecycle management (CLM) rather than traditional purchasing and follows government accounting rules. In addition, banks have back-office settlement processes to reconcile checks, credit cards, debit cards, and other instruments.

Different solutions cater to a wide variety of organizations and requirements.

For example, industries that use ERP to run their businesses include:

- advertising and digital media

- consulting

- education

- energy

- media and publishing

- manufacturing

- food and beverage

- retail

- transportation and logistics

- wholesale distribution and many more.

Key features of ERP systems

ERP systems typically cover all aspects of business operations and commonly provide:

- An integrated system

- Common database

- Real-time operation

- Support for all applications/components

- Common user interfaces across applications/components.

- On-premise, cloud-hosted, or SaaS deployment.

ERP software has the ability to collect and compare metrics across departments and provide several different reports based on roles or specific user preferences. The data collected synchronize reporting and automation by reducing the need to maintain separate databases and spreadsheets that would have to be manually merged to generate reports. This collection offers valuable insight, such as where to cut costs and streamline processes, providing the information to make real-time business decisions.

How does the ERP system work?

As companies need to change and expand, their systems should keep up with this process. ERP work by using a defined, standard data structure. As a result, information entered by one department is immediately available to authorized users across the business. This uniform structure helps keep everyone on the same page. For example, a local printing shop chain has multiple locations that often share stock and personnel. As a quality, sales, and employee data from these sites is fed into the ERP system and formatted to indicate which location it comes from.

Data is then woven into business processes and workflows across departments. For example, leaders can see if one location is doing significantly better than a sister site a few towns over and work to figure out why. Operations can make sure staffing levels align with traffic patterns. Finance can compare sales to rents to help executives decide whether to consolidate.

Ready to Streamline Your Shop Floor?

Simple to use, yet effective online manufacturing software that puts you in control.

Get started today14-day free trial - No credit card needed - Unlimited free support

Different types of ERP systems

Various ERP models address the needs of different organizations, but there are four main types of ERP based on deployment options:

Various ERP models address the needs of different organizations, but there are four main types of ERP based on deployment options:

On-Premise ERP software

On-premise is implemented onsite and maintained in physical office space within an organization, hosted on the company’s own computers and servers for full control, support and ownership of the entire system once implemented.

Cloud-based ERP software

Cloud-based ERP is a web-based solution known as Software as a Service (SaaS). An organization accesses and stores data on any device with an internet connection, usually through a subscription. The software provider ensures continual support, updates, training, and flexible customizations. Some cloud-based ERP systems have a headless architecture separating the frontend from the backend.

Hybrid ERP software

Hybrid type is a combined implementation of cloud-based and on-premise ERP system solutions. The combination of hosting and deployment services vary – some companies may turn to cloud solutions for certain business needs while sticking with their on-premises systems for other functions. Either way, the cloud systems must be linked to the on-premises platform to ensure a steady flow of information — often easier said than done.

Open-source ERP

Like other open-source applications, open-source ERP is an inexpensive, and sometimes free, alternative that’s suitable for some companies. Many open-source ERP providers allow businesses to download their software for free and only charge a low annual fee if the customer wants cloud access. With more modern web-based interfaces and a growing number of modules, these solutions have improved, but companies need to understand what they’re taking on with an open-source ERP.

Support from the provider will be minimal, and configurations and system improvements will fall on the client. That means you need technical staff with a deep knowledge of developing and configuring the software.

ERP Systems by business size

Small-business ERP

Small firms should map out their requirements before starting a search (for example, on Smallbiz Tools) to avoid software with far more functionality than they need. That’s why cloud ERP is generally the best option for small businesses — it offers the scalability to meet the business’s needs as it grows.

Midsize-business ERP

Midsize companies should demand a platform that can support all their business functions with specialized modules and, like smaller firms, select a vendor capable of scaling to meet future needs.

Enterprise ERP

Enterprises should opt for software that can support different components of their businesses. Corporations require systems that can capture, process and interpret a vast amount of data and handle the demands of many business units.

Benefits of ERP Systems

Workflow visibility

With all workflows and information in one place, employees with access to the system can see the status of projects and the performance of different business functions relevant to their jobs. This visibility may be precious to managers and leaders, and it’s far faster and easier than searching for the right documents and constantly asking colleagues for updates.

Reporting/analytics

Data is useful only if companies can analyze and understand it; an ERP helps with that. Leading solutions have impressive reporting and analytics tools that allow users to track KPIs and display any metrics or comparisons they can dream up. An ERP provides an audit trail by tracking the lifecycle of each transaction, including adherence to required approval workflows.

Automation

By automating many simple, repetitive tasks, you minimize errors and the need to add employees at the same rate as business growth. Cross-company visibility makes it easier to spot inefficiencies that drive up costs and leads to better deployment of all resources, from labour to inventory to equipment. On top of using ERP for this purpose, companies can also opt for marketing resource management tools to automate more marketing-related tasks.

Business insights/intelligence

Because ERPs can access data from across the company, these systems can uncover impactful trends and provide extensive business insights. This leads to better decision-making by organizational leaders with easy access to all relevant data.

Risk management

ERP technology reduces risk by strengthening financial controls. More accurate data prevent mistakes that could lead to lost sales or fines.

Collaboration

ERP solutions make it easy to share information — like purchase orders, contracts and customer-support records — among teams.

Disadvantages of ERP Systems

Although ERP systems have certain values, they have some disadvantages due to the tight integration of application modules and data. In addition, huge storage needs, networking requirements and training overheads are frequently mentioned ERP problems and the major reasons for ERP dissatisfaction. The other shortcomings of the ERP systems include:

High costs of this system

It is calculated that customers spend between three and seven times more money on ERP implementation and associated services compared to purchasing the software license or some simple cloud-based software solution. ERPs require time and financial investment hence the technology is much more affordable to larger enterprises. High cost prevents small businesses from setting up an ERP system.

Specialized training

A lack of trained people may affect ERP’s efficiency. The ERP’s functionality depends on proper training; many staff might be resistant to that. An ERP system is loaded with features that can be daunting to your workforce. You need to hire a company to direct the implementation process, and still, the project might be painful, and customisation is costly and time-consuming. Not only does a company need an IT staff to handle patches, security and required system upgrades, it often has to pay the vendor or a third-party service provider for its expertise.

Data

When moving to a new ERP, you may need to convert some data into a format compatible with the new platform. This can lead to unexpected costs and delays, so review your databases, and work with your IT team or an integration partner to identify potential data compatibility issues early on.

Flexibility

To fully use any ERP software, you must feed it a lot of data. That can jeopardize flexibility, especially in a small company. Unless you enter every detail into the system, it won’t allow you to make any quick adjustments. So you might feel limited by that.

Doesn’t solve process and policy issues

If you have error-prone or inefficient processes, ERP won’t necessarily fix them, even though it may increase accuracy. The same goes for policies that hold the organization back — it’s up to you to adjust those and then configure the system to support better ways of doing business.

Company culture

You should remember that an ERP system is not just a pure software package tailored to an organisation but an organizational infrastructure that affects how people work. It is as if it imposes its own logic on a company’s strategy, organisation, and culture.

The point is that ERP systems are not the evil of this world, and we criticize them just as competitive solutions. Many companies may benefit from implementing an ERP system, just not small business.

Ready to Streamline Your Shop Floor?

Simple to use, yet effective online manufacturing software that puts you in control.

Get started today14-day free trial - No credit card needed - Unlimited free support

Is an ERP a smart choice for a small company?

Suppose you are an owner of a fast-growing manufacturing business and want to keep up with the company’s needs. You picture yourself as a successful businessman thriving over rivals, leading your company into changes and the digital revolution. As a manager, you wish to be like a magician performing in front of a cheering crowd of spectators. The wizard pulls stunt after stunt, and the audience admires his dexterity and mastery. He expertly deals cards in the centre of the stage, and although you don’t believe in magic, nonetheless, feel charmed by his performance. Then, when you think it’s the end of the show, he still manages to surprise you with an ace upon his sleeve and gathers a round of applause.

You might ask, what’s this got to do with production scheduling and the choice of online software? Managing to manufacture is a serious business, not just tricks and fun. Well, let us explain the analogy and show you that having the upper hand proves very practical in both cases: a magician’s performance and when you want to surpass your business rivals. Thanks to easy-to-use online management software, you can take the centre of the stage and deal with all the cards. How is that possible? Read on.

Once you’ve got a good grasp of what ERP is, it makes sense to discover different ways to help your business stay organized — optimizing your costs and operations to help you make data-driven decisions that improve your business performance.

ULTIMATE GUIDE, WHICH HELPS YOU TO CHOOSE THE RIGHT SOFTWARE.

Production Management Software or ERP for Small Manufacturers

Production management software – this is a phrase you probably typed in Google searching...

Choosing the most suitable system

For the majority of small companies, the decision to choose the right software is critical. Moving from chaos, paper notebooks, and little or almost no traceability/working time management into a paperless, digitized environment is a huge step.

On the other hand, midsize organizations lack large IT teams, sophisticated equipment, and big implementation budgets. So, to lower the expenses of the digital revolution, they search for user-friendly, inexpensive solutions designed for a company with limited technical expertise.

No matter what size the company is, owners and managers generally focus on outcomes — using the information to achieve objectives, like increasing efficiency, reducing costs and responding to changing consumer needs or market conditions.

Purchasing manufacturing software is a big decision, so take the time to evaluate all options thoroughly.

Why is the ERP system not the best idea for a small manufacturing company?

Theoretically speaking, ERP systems are, for manufacturers, a dream come true. That’s why you might be surprised to learn that most implementations end up in disappointment, where a small company spends thousands of dollars on investment and returns to Excel or other simple solutions, such as Prodio.

ERP disappointments

The most crucial difference is that a small company assumes the system will automatically guess what they need, but unfortunately, it doesn’t work like that. Advanced ERP systems are incredible technological and mathematical creations. This allows them to automate technological processes in large factories producing thousands of elements. When there are thousands of orders at the production line every day, and a man can’t monitor them, all ERP systems thrive. They make sure the right parts are at the right place and time — pure magic. ERP needs data regarding the present situation, the number of employees on the shop floor, their holiday schedule, production line status, and the queue of tasks for 2-3 months upfront. Only having completed these conditions can you plan production.

You can take the best, worth a couple of million ERP systems with artificial intelligence, but there is no way it would work in a small company.

Why is ERP a bad idea for a small company?

Flexibility and custom production

There isn’t time for the team to spend 1 hour on entering all data into the system, dividing the product into smaller parts, logistic minimum, surplus material, or material loss. The Client places an order, and its due date is “for yesterday,” which means all these preparatory jobs have to be skipped, and the system lacks operational data from the start.

Sometimes there is a need to pass by the system due to its inflexibility. A good ERP system won’t let you send an order to production when there isn’t a suitable raw material entered or technology, even though you know this material is available. The technology could be completed on the go – that’s the trouble with using ERP.

Imprecise data

Nobody cares about the % of losses, creating alternative technology, additional stock/ inventory, or schedules of machine downtime, not to mention even more advanced data.

Data mistakes

Mistakes copied from the production panels create chaos in the whole system Let’s assume that an employee makes a typo writing ex. 10 pieces instead of 100, or they click the wrong product. ERP systems automatically count and remove the given number of items from the stock, which works like a domino effect and spurs even more incorrect decisions.

Many years of experience have proved that most companies implementing Prodio want something that would make their lives easier. Therefore, they work not only with ERP but also with Excel. Why? If you can’t trust everything you have in your ERP system, there has to be somewhere else where you store your data safely, so naturally, you put your trust in Excel.

The alternative – a simple manufacturing software

Tailored software can automate many error-prone tasks, like order processing and provide the information teams need to operate more efficiently. So when you run a small or mid-size company, you look for certain features that help you organize and manage workflow more efficiently.

You wish to:

- Organize your production by regaining control and learning about real cost and productivity,

- Identify patterns and flag anomalies that require investigation.

- Provide fast communication between the manager and shop floor and a clear vision of the working schedule and parameters.

- Secure quick effects, functionality, and simplicity (reducing functions that aren’t necessary).

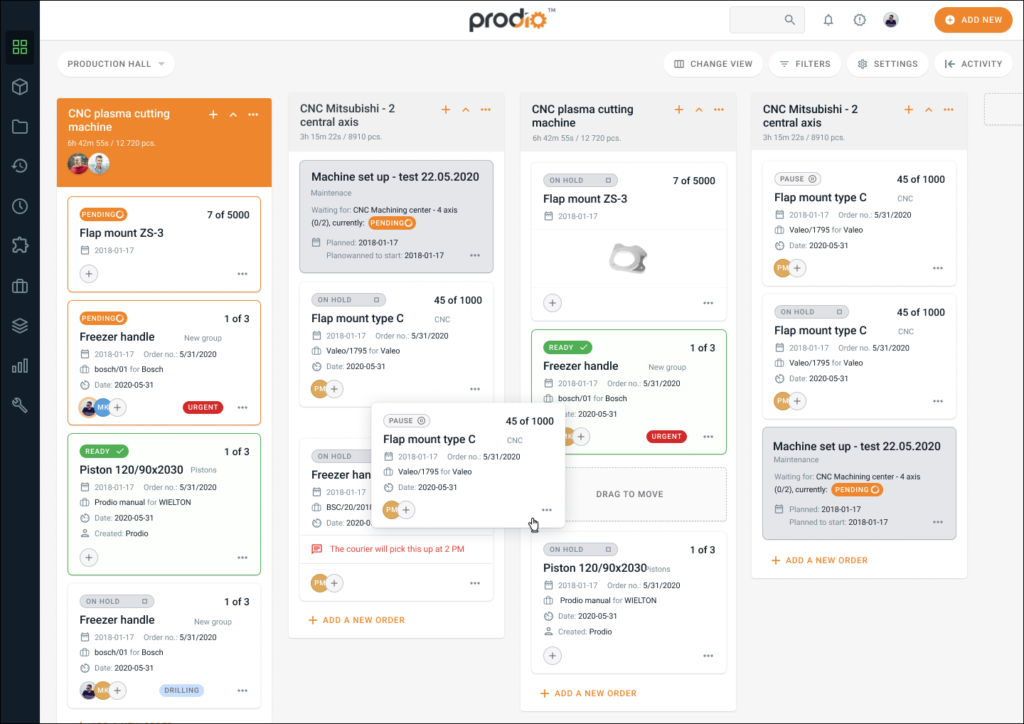

Simple manufacturing software such as Prodio helps you organize and manage your orders so your team can work faster and smarter. Anticipate off times, vacations, and sales reservations and get accurate availability information.

Other advantages include:

Access to data from anywhere

Employees no longer need to shuffle through piles of papers or files scattered across a desktop. With a cloud-based solution, a warehouse manager can log in from a mobile device while on the shop floor, or a salesperson can check inventory at a customer site.

Information is always up-to-date

Because the system continually receives information from various sources, it’s updated immediately. This provides a major advantage because decision-makers are basing their choices on up-to-the-minute data.

Business decisions based on the same data

With a common database, all decision-makers are on the same page. There are no duplicate or conflicting sources of information, and companies have the ability to schedule and distribute dynamic reports automatically.

Communication and cooperation

Simple online software knocks down walls between departments by giving employees appropriate access to data on related business functions. The communication flow is easy, resulting in fewer mistakes, increases transparency and minimizes complaints.

Prodio – a smart option for smal or midsize companies

An ERP is a critical business system that must mesh with each company’s operations, so there is no “best” platform. Instead, required capabilities, preferred deployment model and company size will affect your decision when choosing a production management system.

It is a good idea to start with something simple and build from there. For example, mid-size companies often begin with Prodio software to automate basic accounting tasks and allow managers to easily view the flow of money into and out of the organization. Products-based companies typically want to digitize inventory and order management immediately and simplify employee time, resource tracking, and project billing.

Using Prodio, you can organize your production schedule in any way that is convenient for you – and add changes or updates to it in a flash. Do you want to see how it might work with your own schedule? Then, how about you will meet us for a demo presentation or try out our free 14-day trial? We can bet that soon,you won’t imagine creating your schedules in any other way.

Conclusion

Purchasing and implementing manufacturing scheduling software can be intimidating, even overwhelming. But the solutions available today allow companies to take it one step at a time and add what they need when they need it. Never before has this been within reach for even the smallest companies, and it is good to take advantage of that.

ERP FAQ

What is an ERP platform?

An ERP platform, short for Enterprise Resource Planning platform, is business management software that integrates various core business processes and functions into a single, comprehensive system. It helps organizations streamline and automate their business operations, including supply chain management, inventory management, project management, accounting, and more. ERP platforms provide a centralized database enabling real-time data sharing and improving efficiency across the entire business.

How do ERP platforms work?

ERP platforms work by consolidating data and processes from different departments and functions within an organization into a unified system. They use a common database, allowing information to be shared seamlessly across departments. ERP platforms automate manual tasks, provide real-time data visibility, and enable efficient resource planning and allocation. They facilitate collaboration, streamline workflows, and support informed decision-making by providing a holistic view of the organization’s operations.

What are the key benefits of an ERP platform?

ERP platforms offer several benefits, including improved efficiency, enhanced productivity, streamlined processes, better data management, and increased visibility into business operations. They eliminate manual processes, reduce errors, and provide real-time data for informed decision-making. ERP platforms also enable better supply chain management, integrated financial reporting, and improved customer relationships. Additionally, they support regulatory compliance and scalability, making them valuable for businesses experiencing rapid growth.

How does an ERP platform support supply chain management?

By providing end-to-end visibility and control over the flow of materials, inventory, and information across the supply chain. It helps optimize inventory levels, track orders, manage suppliers, and streamline procurement processes (like procure to pay software does). ERP platforms facilitate efficient demand forecasting, production planning, and logistics management. By integrating supply chain data and processes, they enable organizations to make data-driven decisions and enhance overall supply chain efficiency.

What is the difference between on-premises and cloud-based ERP platforms?

On-premises ERP platforms are installed and operated locally on a company’s own servers and infrastructure. Cloud-based ERP platforms, on the other hand, are hosted and managed by a third-party provider on remote servers accessible via the internet. While on-premises ERP provides more control over data and infrastructure, cloud-based ERP offers greater flexibility, scalability, and cost-effectiveness. Cloud ERP allows users to access real-time data from anywhere, anytime, using various devices.

Ready to Streamline Your Shop Floor?

Online manufacturing software that puts you in control.

Get started today14-day free trial - No credit card needed - Unlimited free support

Marek Mrowiec

Marek Mrowiec