The beginning of June and International Children’s Day is a great excuse to try and test a few new solutions. In Prodio, we know that grown-ups also like to have fun, so we prepared for some cool features. There you go:

1 Register work with QRcodes

Why?

You are free to choose how you want to register work, monitor progress on tasks and track working time and attendance.

There are a few methods available at the moment:

- by using PIN codes,

- by RFID readers and key-fobs,

- by scanning barcodes with the reader (there is more good news: you can generate codes directly in the app).

And now there is an additional, even more, COMFORTABLE way to use your time tracking solution and monitor clock ins and clock outs. Using a built-in camera in your computer or tablet, you can automatically scan the QR code for each worker. It works analogically to key-fobs or RFID cards, but instead of scanning them, you can scan the code on a printed ID card with a camera.

The benefits:

- change any device into a QR code scanner,,

- anytime print new QR codes badges, with codes existing in the system, in case they got lost or damaged,

- minimize the risk of mistakes – each ID card is signed with a full name and you can add a worker’s photo for your convenience 🙂

- less equipment around the computer at the shop floor – forget scanners or RFID reader – the built in computer or tablet camera is enough,

- minimize the risk of “buddy-punching”,

- QR codes become a more and more popular solution in different areas of life – by using them your company joins hundreds of modern businesses!

How does it work:

QR codes are custom made for each worker and available in the bookmark Workers.

Watch the film to see how it works on the shop floor:

2 Adding photos from the shop floor level

Why?

Some of our clients inquired about the possibility of adding photos from assembly or photos of already finished elements. That’s why we decided it is a handy feature and enabled workers to add pictures directly from the shop floor!

The benefits:

- you can see how the product looks after assembly,

- you can create a database of most common mistakes and defects,

- you have photos of finished elements, which you can copy later into the product database.

How does it work?

When the worker finishes working on the production task, they choose an option: Add a photo, then take a photograph with the camera and upload it into software 🙂 You can see it in the work history, and of course, you can save the photo on your drive.

Ready to Streamline Your Shop Floor?

Simple to use, yet effective online manufacturing software that puts you in control.

Get started today14-day free trial - No credit card needed - Unlimited free support

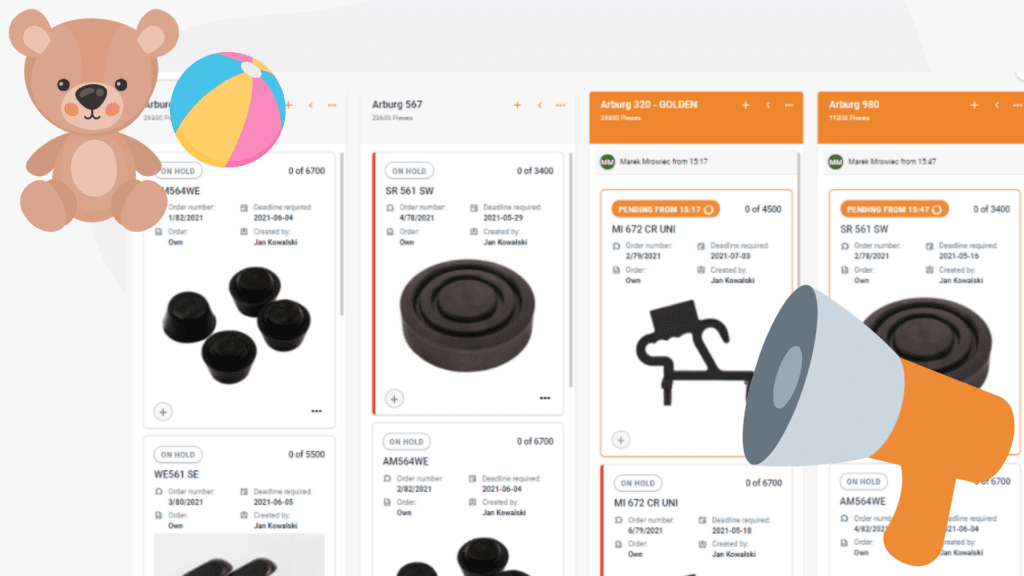

3 Product photos on the production schedule:

Why?

To make work with Prodio as easy as possible! For example, you often asked whether it is possible to see the thumbnail photo of the product on the production schedule without the need of going into order details. Now it is possible, and you can see which product is being made.

The benefits:

- you don’t have to open order details to see a photo of the product,

- your workers can find orders even faster, because of product photos on the production schedule,

- you minimize the risk of mistakes, as the photos show your products clearly.

How does it work:

Go to settings, then switch this option on in the custom settings of your production schedule.

4 Add photos to your workers profiles

The benefits:

- it is easier to find yourself on the list, once you see your thumbnail photo there,

- you can add a worker’s photo to a printed QRcode ID.

How does it work:

Go to the workers and then edit the specific worker. After saving the changes, the thumbnail photo will appear on all lists and the shop floor.

5 Automatic tips for raw materials

Workers don’t have to count how much raw material was used – the software suggests the amount according to set norms – they can either accept it or write a different quantity.

How does it work:

Go to Settings -> Main settings, choose Production schedule and mark the “Raw material tips.”

We hope that you will have fun testing new features. Let us know how you enjoy and use these solutions! 🙂

Ready to Streamline Your Shop Floor?

Online manufacturing software that puts you in control.

Get started today14-day free trial - No credit card needed - Unlimited free support