Production planning in a small manufacturing company is very different from the big factories’ advanced working plans (and varies from theory and production process methods learned during university education). It’s often much more complex and requires a different approach!

Despite all the bluster about semi-automatic planning, hundreds of detailed tables and charts and other hokums, which you find on the websites of providers of advanced software for production management, they can give you more trouble than it’s worth. You will be left with paper orders and chaos at the production hall.

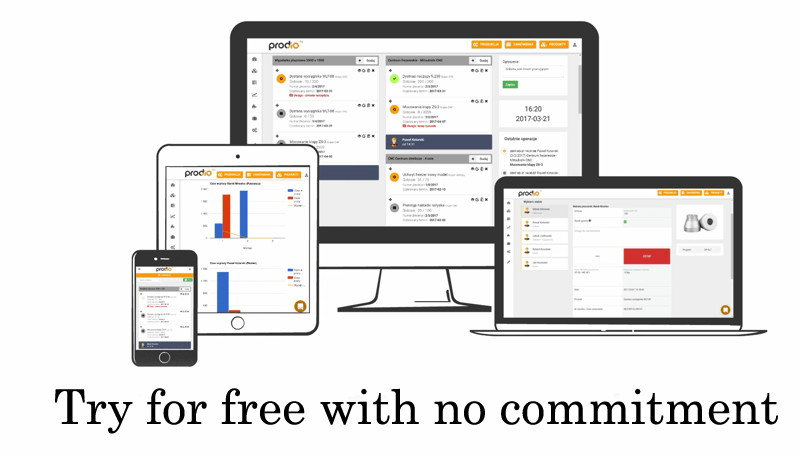

Get rid of paper orders and track your production right now!

Online manufacturing software that puts you in control.

14-day free trial - No credit card needed - Unlimited free support

Many companies are still using old-fashioned production planning methods: they might have worked, but in the past, there were mainly big factories with lots of workers and machines. The production structure is much more varied: there are numerous small manufacturing companies, and the old style does not apply to them. It will do more harm than good.

There is good news: if you tackle production planning using suitable tools, making it clear and understandable for everybody, streamlining the manufacturing process is within reach. Especially at the time of accessible Internet tools! 🙂

Instead of having tons of handwritten orders which need coping into Excel, you can have an online, neat dashboard and enjoy a paperless production planning process.

What is production planning?

Production planning is the planning of production and manufacturing modules in a company or industry. In other words, this is your strategy for the whole manufacturing process. The plan works as a guide: it shows what should be done, in which order, and how quickly to achieve the desired result. Production planning can help efficient manufacturing or set up a production site by facilitating critical needs.

There are different production process methods, such as single-item manufacturing, batch production, mass production, continuous production, etc. Each of them has its type of production planning. From clever production planning and scheduling comes reasonable production control. These processes are naturally combined. When you have excellent production control, you are sure that all the necessary raw materials, tools, knowledge and people are there, so you know how much you can produce at any given time.

What should be your primary objective regarding production planning?

Objective 1: The employees should know what to do and in which order. Even in your absence.

Imagine a situation: you can go home without worrying or take a short holiday because you know that production will continue, even though you aren’t present. How does it feel? Paradoxically it is straightforward to achieve.

It would help if you had a clear schedule, showing where in the production process you are and what has to be done step by step — instead of a complicated vision when a worker doesn’t know what to do. The idea is to create a simple solution. Then, even somebody, who isn’t familiar with computers or technology, can intuitively use them.

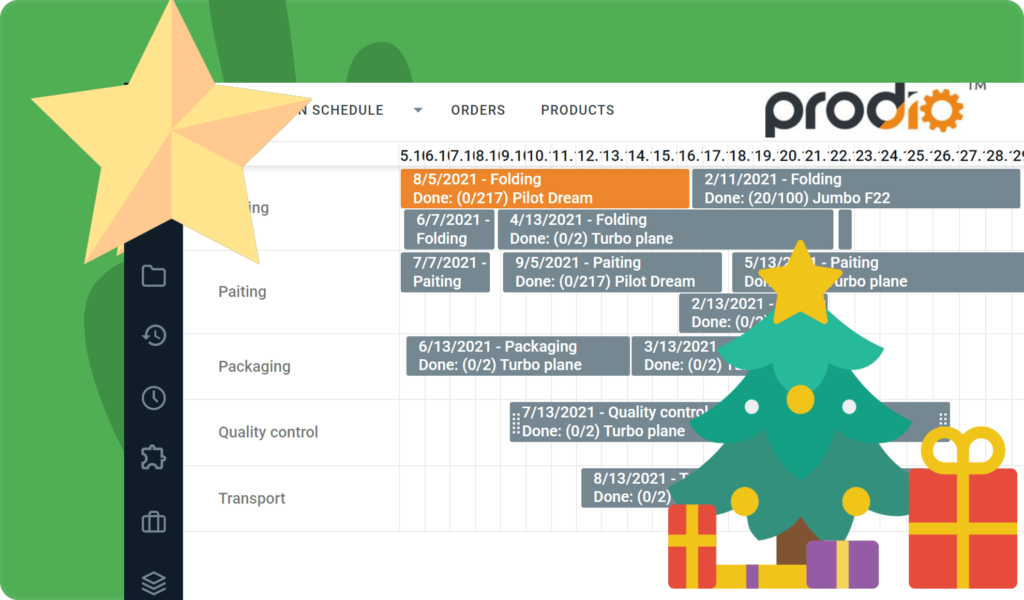

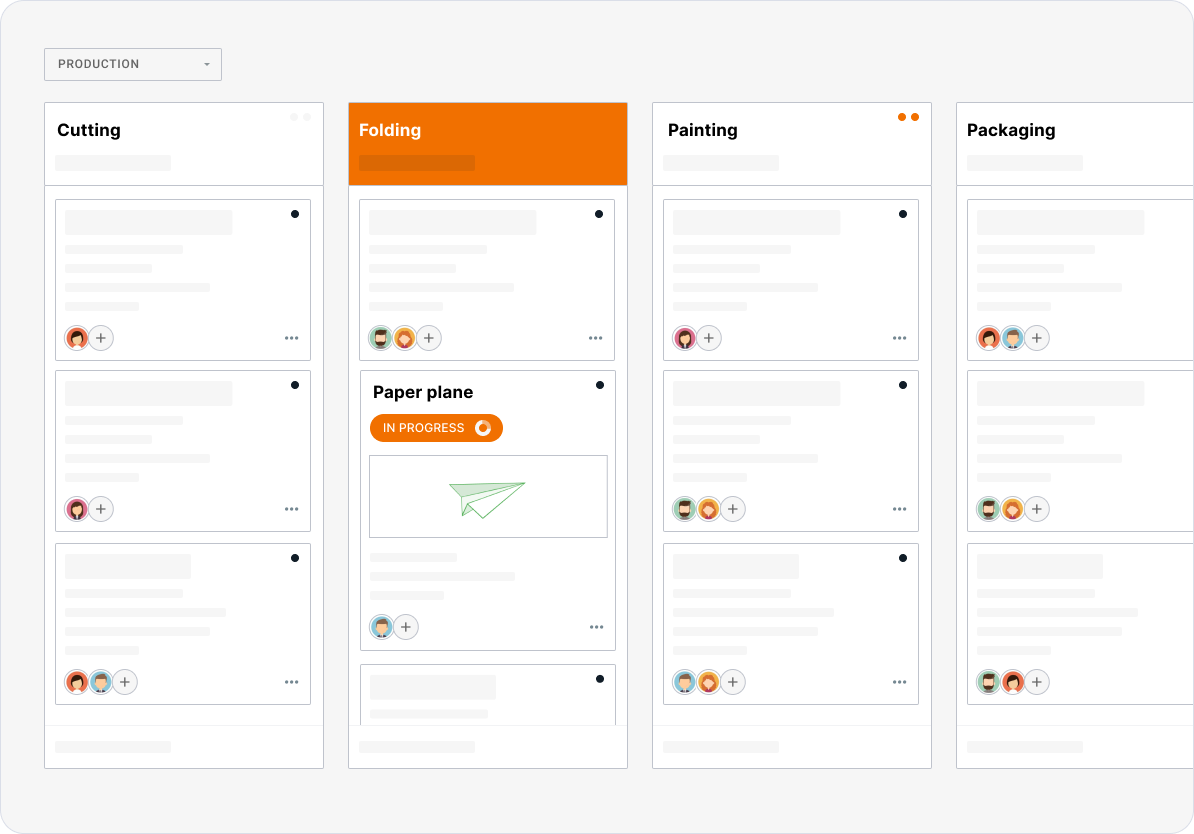

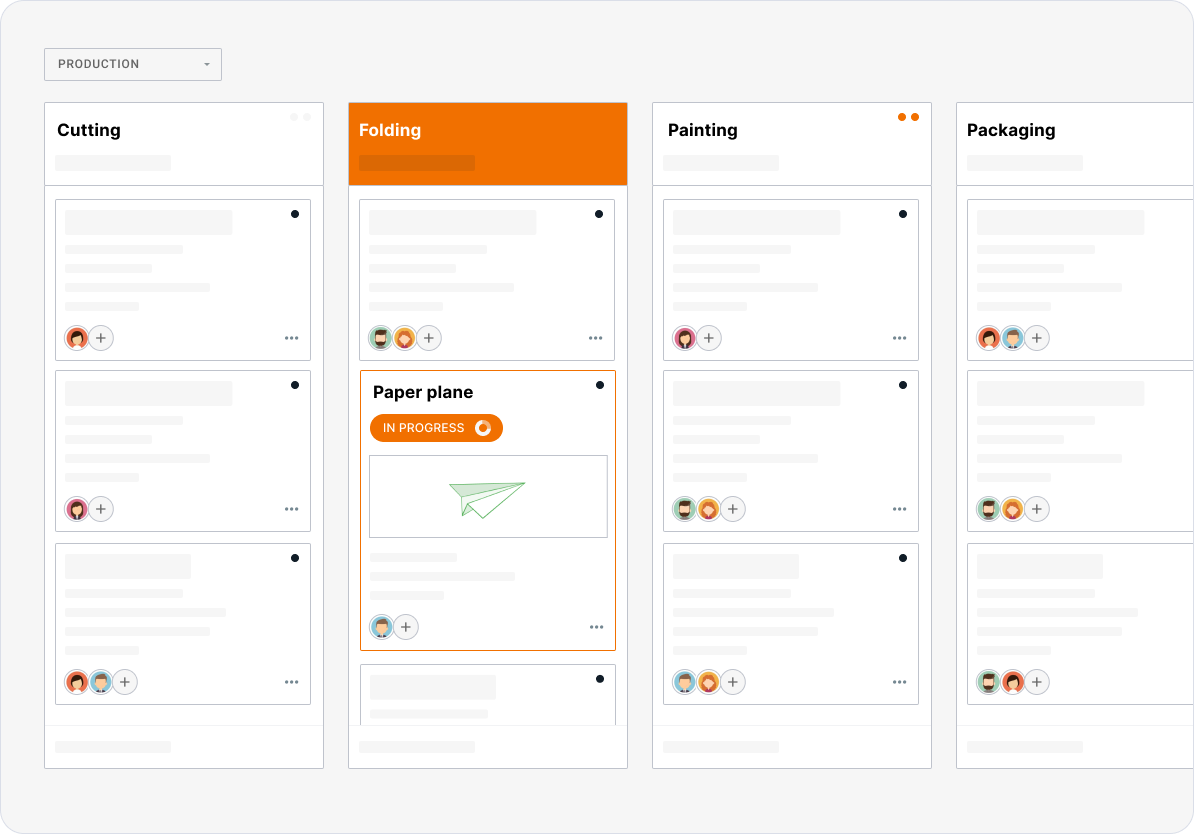

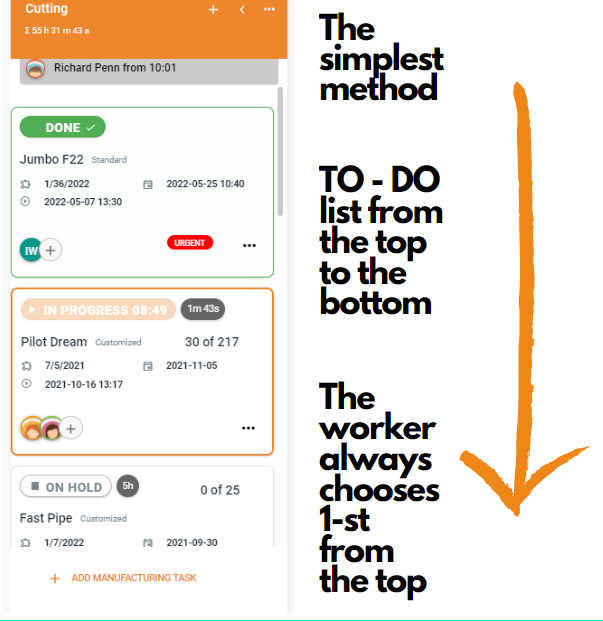

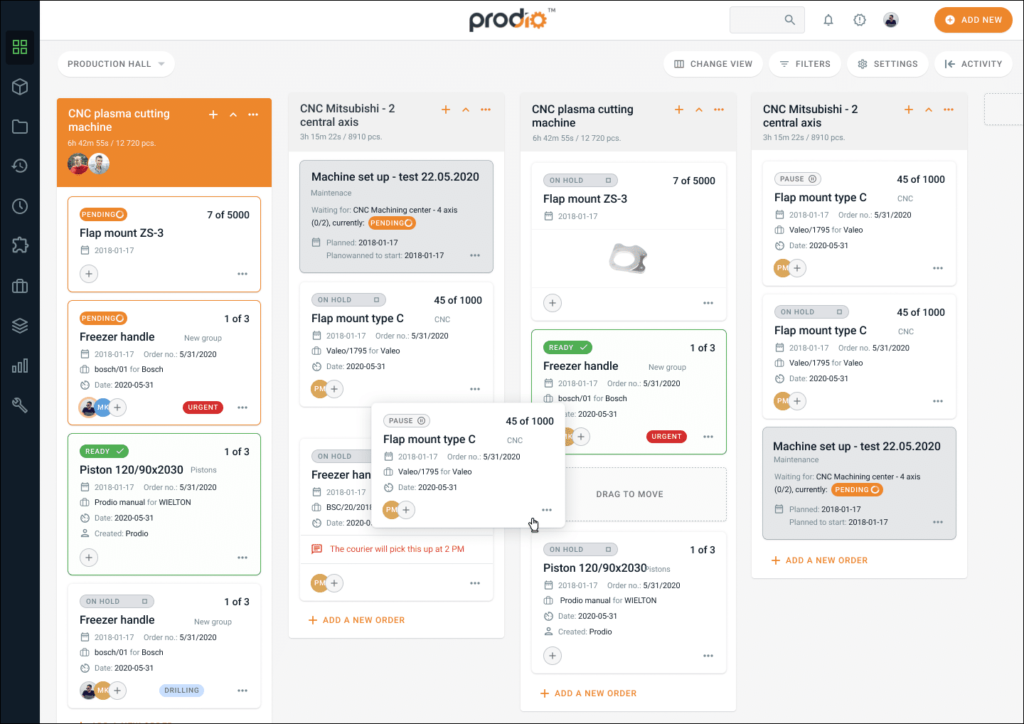

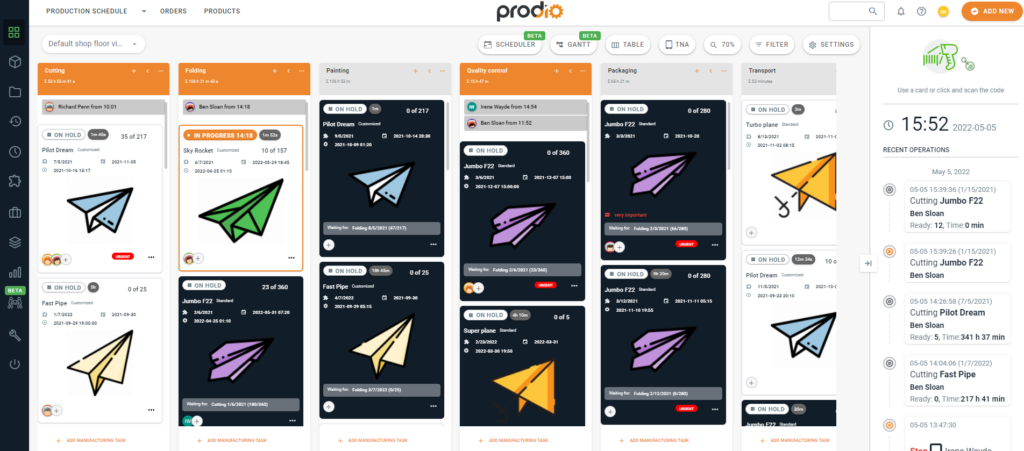

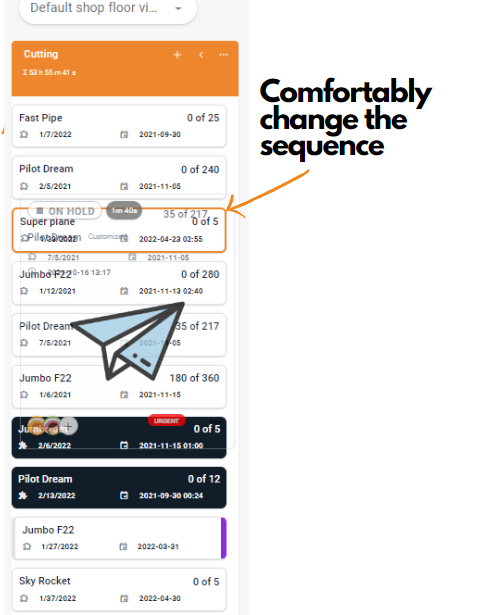

Illustration: the view of the production plan from getprodio.com/pl system – try it for free HERE)

Remember that even when you produce very sophisticated products (which consist of thousands of parts), each person at the production hall has to make a particular element, using that particular machine, accordingly to set parameters, and they have to do it well.

Considering the efficiency of work at the production hall, it turns out that the comment handwritten on the order form by a worker, for example, about changes in technical drawing, is much more important than giving a precise time of starting work.

Objective 2: You must know how much you can produce at any given time, whether you will keep deadlines, and what is your production capacity.

In small manufacturing, it isn’t possible (well, maybe it is, but it would involve the astronomic amount of work) to set precisely a production plan and determine minute by minute when each product would leave the shop floor — in a way that all these projections are accurate — there are too many variables, which would cause the original production plan to change very often.

Luckily you have a super processor — your brain, which has terabytes of experience in production, and it knows how to manage things optimally. All it needs to make a decision is a clear view of individual operations to adjust things accordingly 🙂

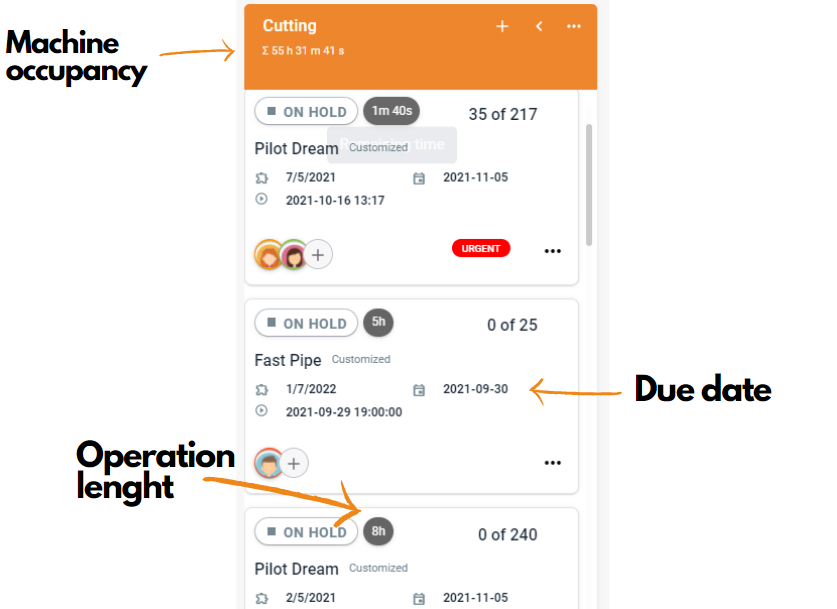

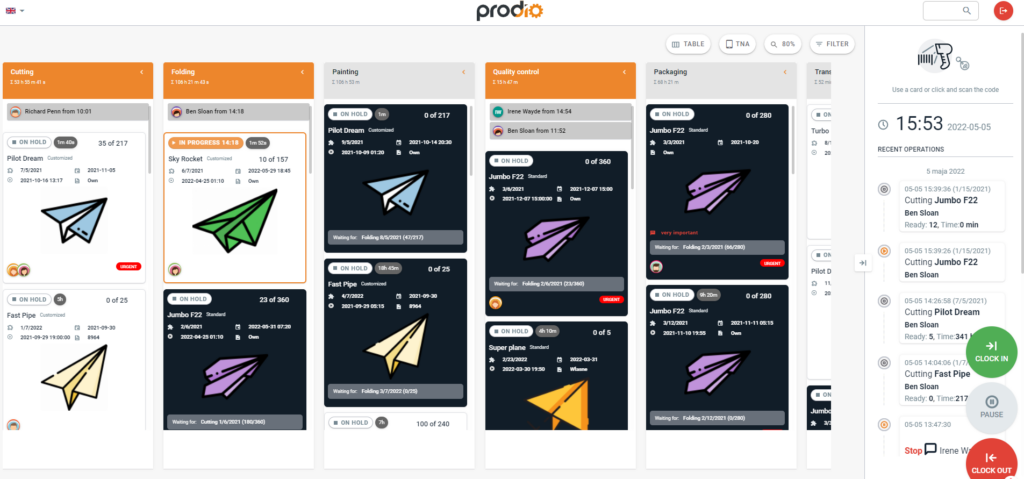

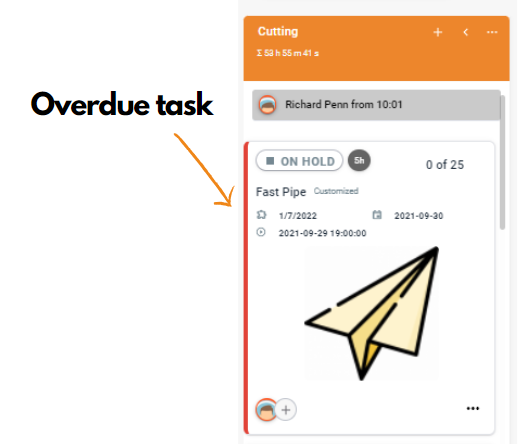

(Illustration: the view of production plan from getprodio.com/pl system – try it for free HERE)

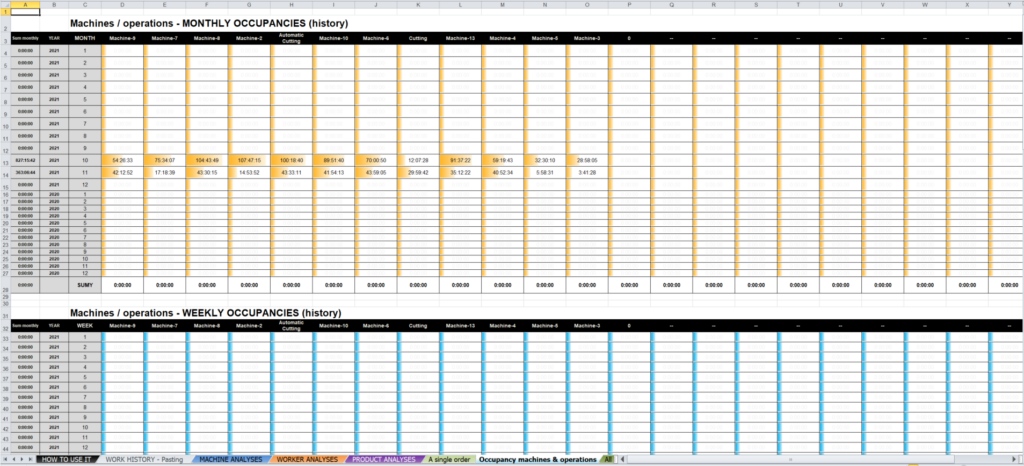

The second element, which enables the supercomputer in your head to work, is a simple overview, which forecasts your machinery’s capacity and operational capacity in months, days, and hours.

It gives you complete control over your manufacturing process. You will feel confident in front of a client and will be able to quickly make accurate estimates, confirm the dates, and negotiate with sales reps;

The system will prompt you that something is overdue and requires you to follow up, or your quick reaction is an excellent advantage and undisputed facilitation.

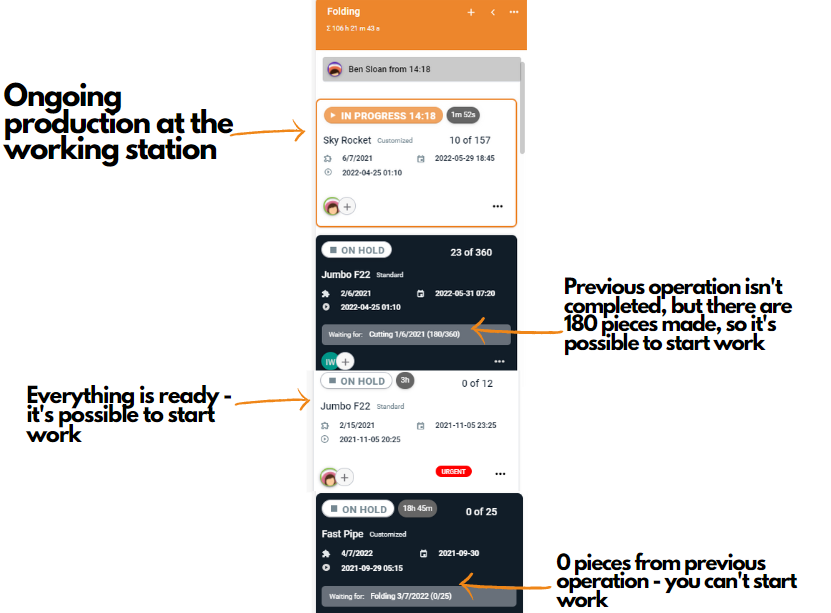

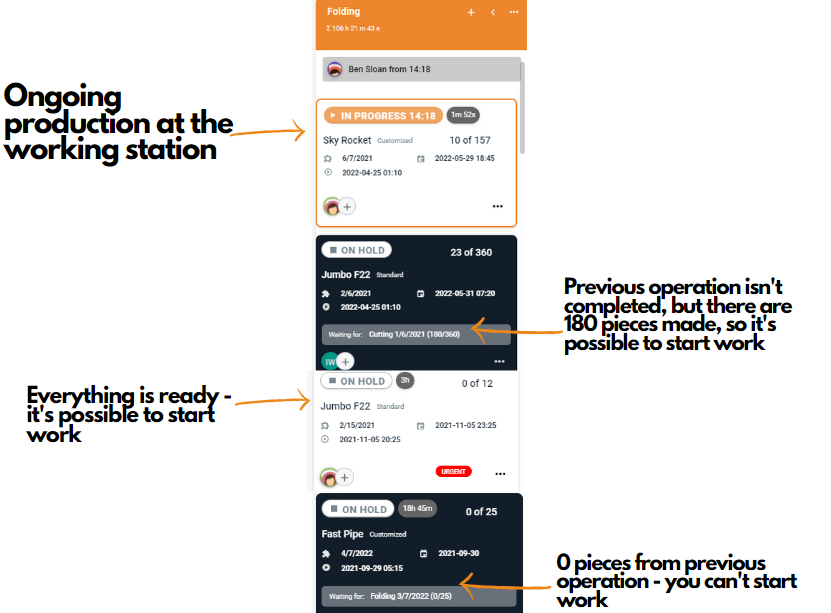

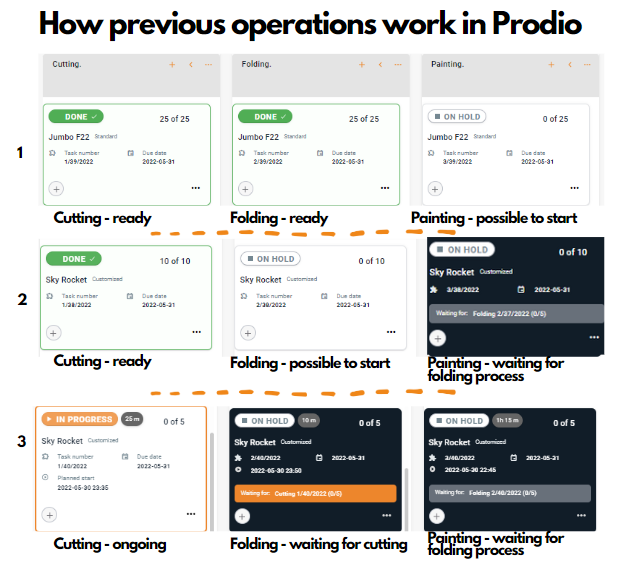

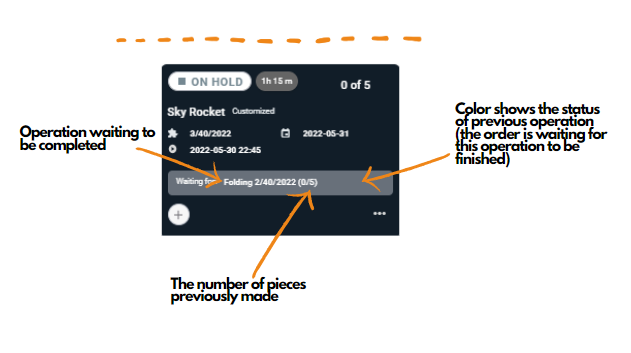

Objective 3: You and your staff must know whether the part was already made during the previous operation.

That’s it — no more running and asking! The bigger the production hall, especially if it has a few floors, wastes more time. Countless questions are about whether it is possible to start work on the said element or still wait for completion at the previous working station.

A good production plan should show employees what they can do and what can be done from the list of operations.

(Illustration: the view of production plan from getprodio.com/pl system – try it for free HERE)

Let’s say that the paint shop has run out of a particular colour. It doesn’t mean that the whole company stopped working — simply, the additional elements are being made instead. If one part of the metal-cutting machine has worn down, nobody will wait for it to be fixed; a different one replaces it. The employee can see it on the production plan, and it is clear that some things have to be skipped for the time being, and the job available can be done. These are the principles of production planning. You have virtually no time to spare; chaos at the production is your constant worry, but don’t put your decision off- it’s a vicious circle. Start today, not tomorrow and make your work take less work. We promise that together we can get your production to the next level!

Ready to Streamline Your Shop Floor?

Online manufacturing software that puts you in control.

Get started today14-day free trial - No credit card needed - Unlimited free support

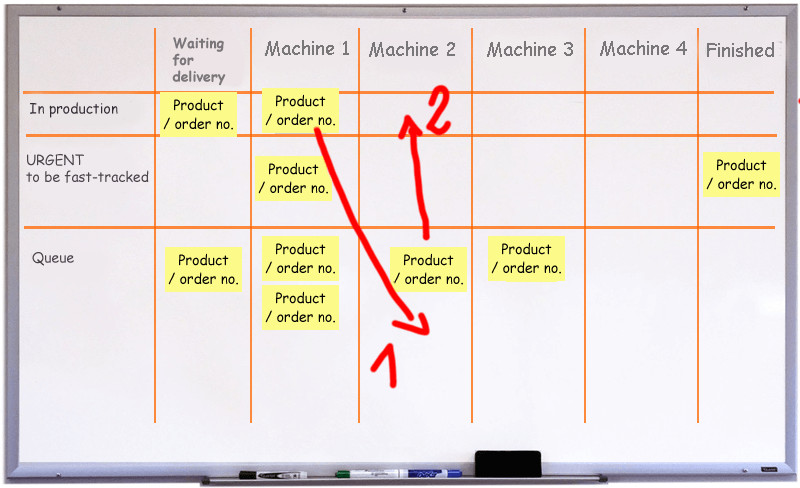

1. Tables in lean methodology or your methodology

This is a typical old school, which doesn’t mean it’s a useless solution because even today, it is used by big factories to visualise a factual situation. All you need is a whiteboard, a roll of duct tape to separate lines, and a bit of imagination to divide things reasonably.

It works in this way: each order is a note, self-adhesive or magnetic, on which the guidelines on how to produce something are given. A production manager sets the queue for particular machines, and the following workers move the notes — if it is a job still in progress, they move the note to the first row, and when the job is completed, it is the last position at the machine.

There are alternatives: you can place boxes by the machines and put inside orders as they arrive; consequently, employees move the orders between each workstation. It is possible to modify the above solutions or buy a dedicated one.

There is an example of whiteboard production planning below; instead of using notes, employees write down pieces made with markers and horizontal orders (own materials).

There is a question of why use such a solution instead of free Trello software or a low-cost monthly subscription at kanbantool.com, which both give much more possibilities.

Trello is, in fact, an easy and free table which can be shared with production. However, although it is a free program, it has some disadvantages, such as a lack of work streamlining or analyses of pieces made (only progress), etc.

2. Production planning in Excel (or even better in Google Docs)

Why plan production in Google Docs spreadsheets, not in Microsoft Excel?

- it is straight away online, and it can be projected at the production hall,

- it is more comfortable and easier to use: although for many years I was working in Excel, after switching to the Google version, I have no intention to go back, mainly because I value comfort the most,

- the online understanding is better at handling a lot of production data (where MS Excel online showed mistakes, Google had no problems whatsoever),

- easier and more intuitive file sharing,

- better surveys offer the possibility to collect production data.

Different types of production planning in MS Excel and examples:

Production processes planning – Excel’s sample (here Google Spreadsheet)

Production plan Excel (Google Docs) with each employee included

3. An easy to use production planning and work registration online software for small manufactures

It is 2022, and displaying a work plan at the production hall is very easy, fast, and most important, practically free. The principles are easy — you decide to leave your tested invoice and inventory management system, to implement a new external tool – Prodio and continue production comfortably without any complications.

No more burning the midnight oil and working the second shift to make sure things are running smoothly. Spend the evening with your family or on your preferred pastime. No more cutting holidays, because the production won’t be functioning without you, no more such dilemmas!

Objective:

Controlled and better-organized production at the shop floor; your workers must know what order should be produced (they always have an updated production schedule at the shop floor). You know the real-time of when the product is ready, can estimate progress and efficiency.

TEST IT FOR FREE – CLICK TO START

It is recommended for:

- industries with simple products: metalworking, CNC, injection moulding machine industry, elastomers, carpentry, cardboard boxes, printing houses, tool shops and other similar production-support services (ex. galvanizing industry),

- producers of equipment/ machinery/ steel structures, where it is necessary to manage separately individual elements of the construction (or group of products),

- the number of employees starting from 2-3 people at the production hall up to about 40.

Typical cost (based on Prodio software):

- Monthly subscription: from 97 USD net per company

- Implementation/setting up costs: 0 USD, the clients start by themselves.

- Update costs: 0 USD (always up-to-date)

- Necessary equipment at the production hall: simple laptop/computer with Internet access, RFID readers + key-fobs

Free trial:

What should the production plan contain to be effective in the management of work on the shop floor?

Necessary data regarding production planning, so an employee would know what to do and how:

1. The list of machines/ manufacturing operations depending on how you plan to work;

2. The queue of orders for individual machines/ manufacturing operations;

3. Important comments, usually given as spoken remarks, not connected directly with product’s technology, ex. that at 2 p.m. the courier comes to collect a particular product;

4. Parameters regarding how something should be made — with a reference number to documentation or external order;

5. Deadline – when is the particular operation due.

Data necessary for simple production and machinery capacity planning:

- Working time of particular manufacturing operations and how they are ordered,

- Total working times for individual machines,

- Indication, what is overdue or at risk of being overdue,

- The connection between orders — the order of manufacturing operations.

What you DON’T need for production planning in a small manufacturing company:

Giving a PRECISE calendar with an estimated time of starting each manufacturing operation is based on scheduling in big facilities. Flexibility is a priority for you, so one phone call from your client would prove it wrong.

System of production planning with Gannt’s charts, etc. Charts are great but to set them up in a way that facilitates production planning would require a great amount of time and precise technologies for each product — otherwise, they would be unnecessary.

Production planning program — why online?

Experience shows that a production floor is where the most common mistakes happen, and this is where the company makes losses. Incorrect interpretation of guidelines given over the phone, obsolete drawings, faulty communication between shifts, errors caused by confusion, and last-minute production plan changes are the grounds for most common production planning mistakes and complaints.

The lack of online manufacturing planning and progress tracking results in:

- Much higher risk of using bad parameters/ making unsuitable products;

- The wrong sequence of works, ill process flow and unnecessary changeovers;

- Hold-ups, during which employees don’t know what to do;

- Missed delivery dates and extended delivery times (lack of knowledge of lead times);

- Long hours you spend on controlling the production hall instead of developing your business;

- Incorrect exchange of information between shifts.

The fact that you don’t have a computer on the production floor is a single reason why you lose a lot of money:

The arguments I CAN’T AFFORD IT/ I DON’T HAVE TIME/ EMPLOYEES WON’T BE ABLE TO HANDLE IT lost their validity. All you need to work in the most efficient way is an online production plan and:

- one of the three production planning programs mentioned at the beginning of this article,

- second-hand laptop or cheap tablet,

- Internet access (Wi-Fi / 3G).

Ready to Streamline Your Shop Floor?

Online manufacturing software that puts you in control.

Get started today14-day free trial - No credit card needed - Unlimited free support

When each worker knows what to do – a simple production plan

That’s it! You will not waste your money!

Have you recently experienced any of the below problems, which cut your profits and caused production delays:

- The workers stand by, waiting for you to assign tasks to them.

- Chaos on the shop floor, even if you put in extra hours, it doesn’t change into increased productivity.

- Instead, the workers wander, unaware of routing and scheduling assignments. They keep asking about progress or whether the element is ready at the next machine, but it is still hard to make a production target.

- Many stressful situations are caused by a lack of control and the inability to pinpoint the status of your order.

- Incomplete information stops you from accepting extra work or slows you down, as you don’t know the capacity of individual machines.

If you answer yes at least once, there is good news – the solution is within your reach in the form of a production planning program.

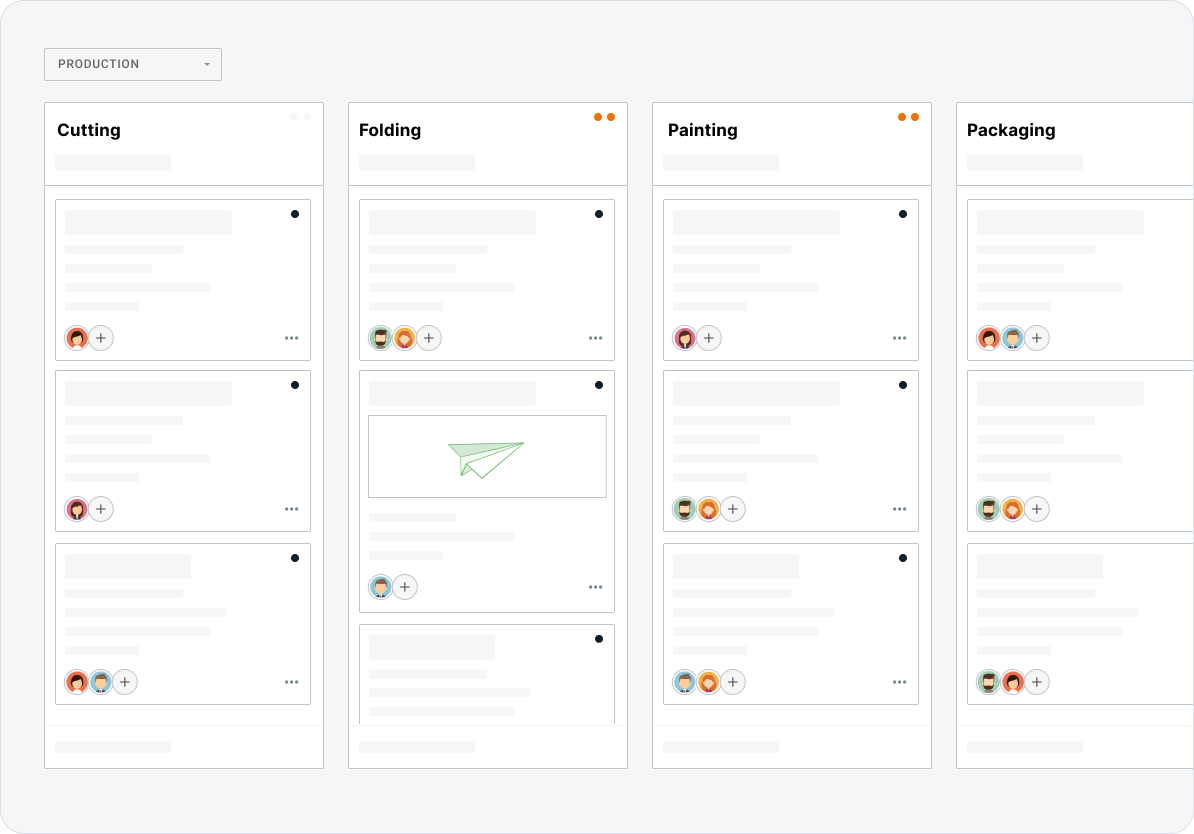

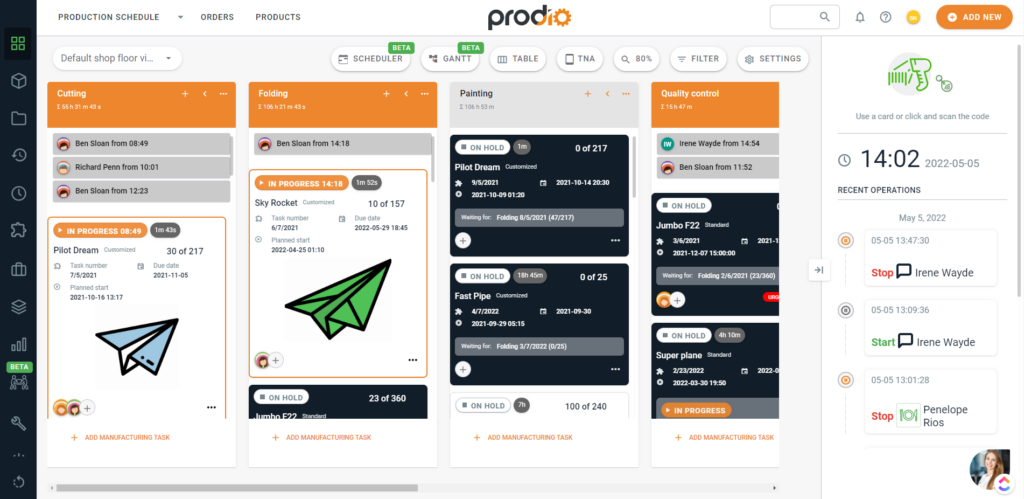

Always updated lists of tasks for each operation or individual machine

Prodio’s production plan

Production plan as an easily accessible list of tasks

What’s the most accessible form of assigning tasks that everybody understands?

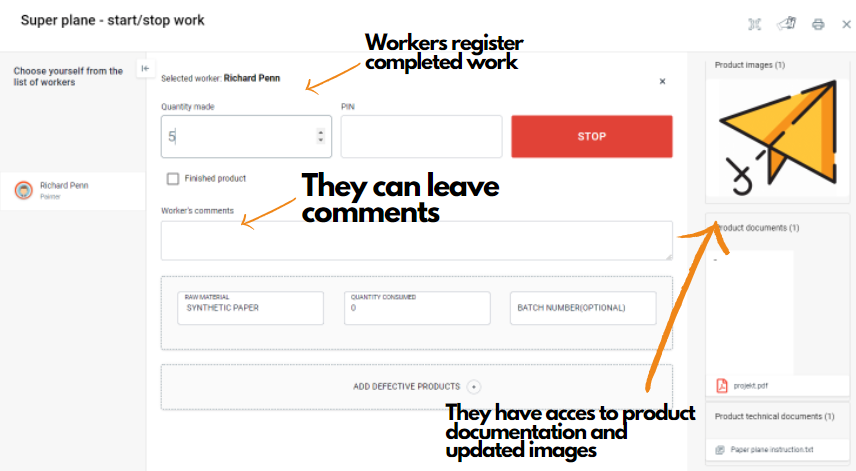

SIMPLE LIST OF TASKS: In Prodio, employees see a production schedule as a list of tasks for each machine/operation and know exactly what to do and in which order.

- The employee always chooses the first from the top task on the list.

- Once the task is completed, it’s marked green or disappears (depending on settings), and the employee can move on to the next task.

Thanks to flexible work scheduling, you can leverage a drag-and-drop scheduler to fix the production queue and work with customized job cards to offer essential assignment insights. Review a visual representation of each work centre load to control new production schedules.

You can change the order of tasks from your computer – drag the particular task up or down to the required position on the production plan. All changes will be visible within a few seconds.

What’s important is that you can react quickly because you see who is working on a particular task and the progress. When there is a problem with completing an order, employees can leave a comment, and you will see it as a pop-up cloud regarding the last operations.

Production planning: a schedule set for machines or operations?

In Prodio, you decide how a production plan will be set by ordering tasks – by simply naming separate lists (Settings -> Machines/Operations). So think about how you see your production and try replicating it in the software.

Tip: different manufacturers use categories such as “Preparing technology” or “Cooperation services” and mark them as operations on the production plan, which allows them to see manufacturing as an overall technological process.

The production plan can be divided into different views for each production floor or group of machines.

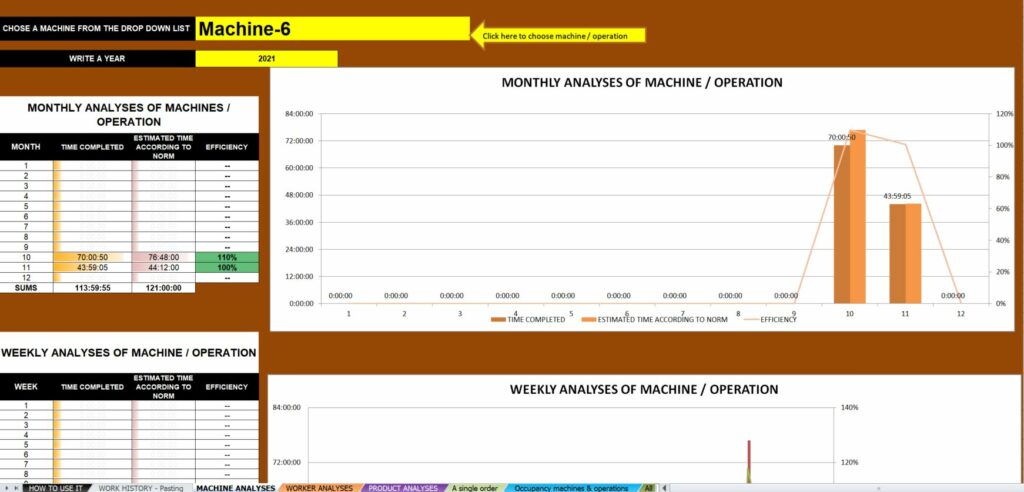

You can see machines’ occupancy, so you never miss a deadline

In small manufacturing, there isn’t time to waste setting a precise production schedule/ There are too many variables, and there is too much work, so the constant corrections would make it pointless.

All you need is a clear view of how much time is left for particular operations, and a forecast of machines’ occupancy – to decide whether you can accept further orders. This is a practical solution you get from preparing a production plan in Prodio.

Additionally, the software will let you know which orders are overdue, marking them red – and you can receive an e-mail with this information if requested.

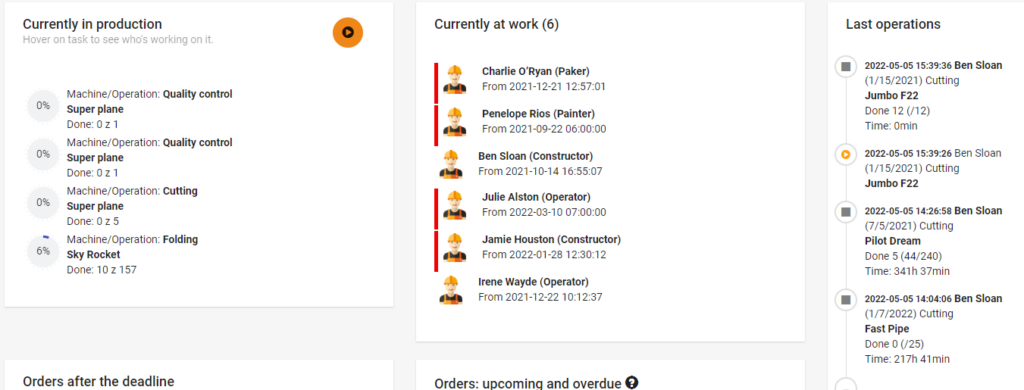

Find out in real-time what is happening on the shop floor and react instantly.

Job Tracking

In Prodio, you obtain a real-time snapshot of shop floor happenings to showcase when jobs are close to completion so you can offer accurate customer updates. Staff can search for manufacturing jobs. It also showcases the next routing step and authorizes close-outs and reallocation responsibilities to alert the next person in the next step for incomplete assignments.

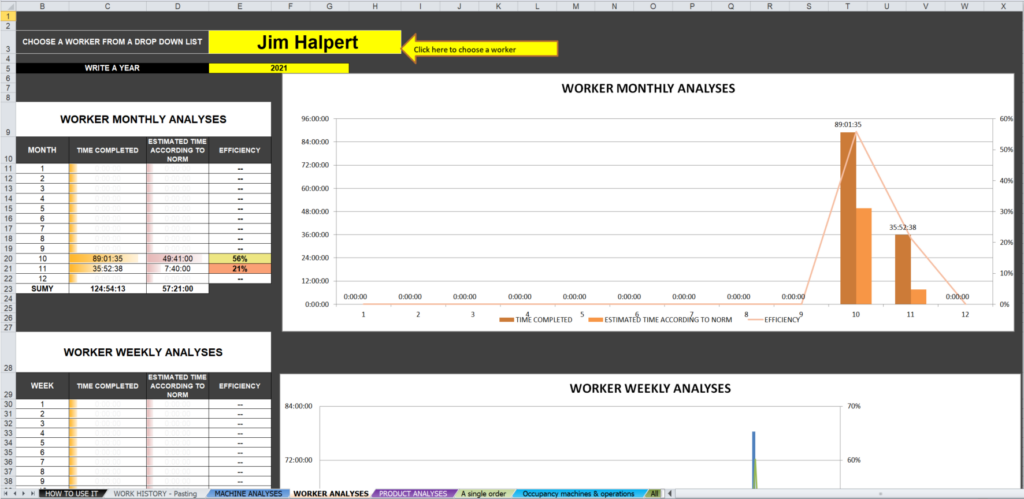

Prodio gives you a complete array of tools for production planning, so at any time, you know:

- Who is working, when they started and whether they completed the machine task.

- Which machines/operations are now in motion, and who is working and where.

- Which stage are particular orders at, and who is working them?

- What and how efficiently was produced, and were there any crucial comments during the production processes?

You can access getprodio.com on your computer and smartphone, so you always have your production.

Your employees will not waste time finding out whether they can start the following procedure or if it is still underway.

That’s it! No more wandering and asking what to do! The bigger the production line, the worse it usually is, and the workers waste time checking whether they can work on the said item or if it’s still waiting for completion at the previous machine.

A good production plan should visually show employees what they must do and what from the list can be made. In this way, people don’t get upset or fed up with working in a chaotic environment, so they won’t go to look for a job; check Jooble.

Apart from marking with the dark colour, the employee at the different shop floors can see what stage the product is at and how much was already completed (ex., can they take the first pieces from the milling machine and start sanding). Production planning software gives a clear answer.

Production planning in a small company – conclusion

Production planning is integral to any successful business, particularly if it is a small company. It enables to maintain inventory levels (raw recourses), plan production schedules, keep production line in order, and develop the overall operational plan. Thanks to good production planning you know your production capacity.

Production scheduling helps small business owners track their resources, create realistic budgets and make informed decisions about production scheduling. With careful planning, the small business owner can identify what resources are available and how they should be used for maximum efficiency. Through this process, a clear understanding of the company’s manufacturing needs can be developed so that products or services can be produced in a timely manner with minimal waste or disruption in operations.

In addition to helping identify resource needs, production planning also helps establish an organized schedule for completing tasks on time. This ensures that there is no downtime in operations due to a lack of resources or failure to meet deadlines.

Ready to Streamline Your Shop Floor?

Online manufacturing software that puts you in control.

Get started today14-day free trial - No credit card needed - Unlimited free support

Marek Mrowiec

Marek Mrowiec