At the beginning of September, Prodio prepared a “back-to-school package” in the form of an intuitive raw material inventory and a few other functionalities that will help you fight inflation and the fluctuating prices of raw materials. Thanks to it, you can do business successfully and have better production planning in a quickly changing reality.

#1 Intuitive raw materials inventory

We have been considering the addition of the new inventory module for quite a while in Prodio. Originally we wanted to avoid it, as it could change the software into something we didn’t want. Prodio manufacturing MES was created as a tool for the shop floor, where progress tracking and work registration are the essential features. Inventory management wasn’t our mind, so we preferred to leave it to other programs.

But things have changed, so never say never! We develop Prodio in a way that responds to our client’s inquiries and ideas. Recently, the world has been changing dynamically – pandemic, inflation, and steep prices of raw materials. It is hard to predict what is going to happen next. Knowing that as a manufacturing company, you can make a profit and price your products or services accurately is crucial.

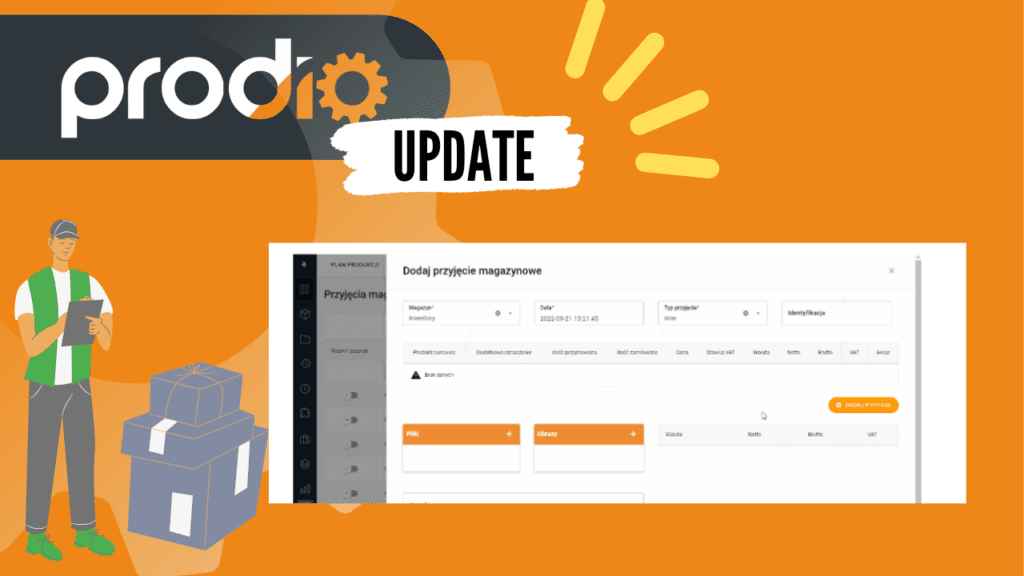

That’s why after all, we decided to create a friendly raw materials inventory module.

How can you benefit from the inventory module in Prodio?

- you can track how the price of raw materials has changed in recent deliveries, and thanks to the average price of raw materials, you can better estimate production costs and react in time to prevent money loss;

- you can view all inventory receipts – you will see how the price has changed, depending on, for example, the suppliers you have chosen, which can help you choose the best and most cost-effective option in the future;

- you can add and manage orders from suppliers – you can see at what stage they are, what prices were given when the order was made, etc. You have a full list of these orders – at any time, you can return to the archives or edit the ones that are currently in progress;

- you can also make receipts and stock releases. For releases, you can print receipts to control the goods more easily.

All in one place, you can click it and see simple tables and charts. And above all: you gain complete control not only over your shop floor but also over the warehouse:)

#2 Other useful features of the inventory module:

- Use one or multiple inventories:

If you choose to use multiple inventories, you can make stock transfers between specific locations, i.e. from the main warehouse to the production floor or somewhere else.

If you use one inventory, the stock will decrease automatically, so no additional steps are required.

Both solutions have their advantages and disadvantages: when you use multiple inventories, you have more control over how the raw materials are consumed in production – it will be easier to catch errors and conduct impeccable warehouse control – you can see when and who sent a given raw material from the warehouse and what happened to it later.

When using one inventory, everything happens automatically, and unfortunately, it can generate errors and negative balances.

- Checking the demand for raw materials

Another thing you have often mentioned was to see simply, with one click, what the demand is in different periods for individual raw materials. In response, we have added a very simple chart that shows you the demand in day/week or month mode.

Below is a simple table with information on which orders you need these raw materials. So in one view, you can see the demand, how much raw material you have in stock, and the largest delivery. This colorful graph in the Demand tab shows your current situation graphically, and it will help you decide which purchases you need to make and react quickly.

#3 Possibility to manually add records to work history and to the Time and Attendance module

Why?

To solve any “unforeseen cases”: workers have forgotten to clock in the production order or register entry to work? Have you had a temporary internet failure and want to add missing records to Prodio? This is quite normal; such situations happen quite often. We have added this new functionality to make it easier for you to complete missing entries in Prodio!

How does it work:

Check out the below Knowledge base entries to learn more: